Why Is the Automatic Concrete Block Making Machine a Game-Changer for the Construction Industry?

2024-12-17

The construction industry has seen numerous innovations over the years, and one of the most transformative is the introduction of the automatic concrete block making machine. This advanced machinery is revolutionizing the production of concrete blocks, paving the way for faster, more efficient, and higher-quality construction. But what makes the automatic concrete block making machine so important for the modern construction industry? And how does it stand out from traditional methods of block production?

In this blog, we’ll explore why the automatic concrete block making machine is considered a game-changer and how it’s reshaping the landscape of concrete production.

1. What Is an Automatic Concrete Block Making Machine?

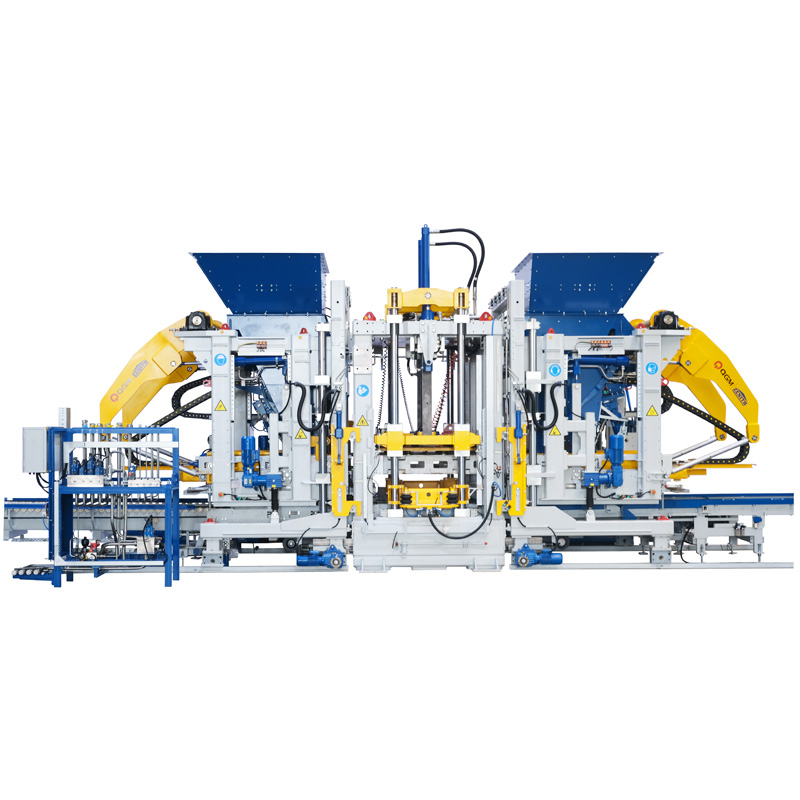

An automatic concrete block making machine is a state-of-the-art piece of equipment designed to produce concrete blocks, bricks, and paving stones with minimal manual intervention. Unlike traditional methods, which rely heavily on manual labor for mixing, molding, and curing, automatic block-making machines use advanced technology and automation to carry out these processes.

These machines are designed to produce a wide range of concrete products in a highly efficient manner. The automation aspect ensures that the production is faster, more consistent, and involves less human error, leading to better-quality products and reduced labor costs.

2. Why Are Automatic Concrete Block Making Machines So Essential for Modern Construction?

#High Efficiency and Productivity

One of the most compelling reasons why automatic concrete block making machines are becoming increasingly popular is their high efficiency. These machines are designed to operate at high speeds, significantly increasing production output compared to manual methods. The ability to produce hundreds, if not thousands, of concrete blocks in a short period of time makes them invaluable for large-scale construction projects.

For companies involved in mass production of blocks or those working on large-scale infrastructure projects, the automation provided by these machines is a game-changer. It allows them to meet tight deadlines without compromising on quality or consistency.

#Consistent Quality Control

Quality control is crucial in construction, and using an automatic concrete block making machine ensures that each block produced meets stringent quality standards. The machine’s advanced systems ensure that the correct mix of materials is used every time, and the molding process is precise. This results in concrete blocks that are uniform in size and shape, with consistent strength and durability.

In traditional methods, inconsistencies in block quality are common due to human error or variations in the manual mixing process. With automation, these variations are minimized, leading to higher-quality products that can withstand the rigors of construction.

#Cost Savings

While the initial investment in an automatic concrete block making machine might seem significant, the long-term cost savings are undeniable. The automation of the production process reduces the need for manual labor, which can significantly lower operational costs. Fewer workers are required to run the machine, and because the machine operates efficiently, it reduces the time needed to produce a large number of blocks.

Moreover, automatic machines often feature advanced features that optimize the use of raw materials, minimizing waste and ensuring that each batch of concrete is used to its full potential. This can lead to significant savings in material costs over time.

#Flexibility and Customization

Modern automatic concrete block making machines are incredibly versatile. They can be used to produce a wide range of products, from standard concrete blocks to specialty items like interlocking paving stones, curbs, and decorative bricks. Additionally, the machines can be customized to meet specific production needs, such as producing blocks of varying sizes and strengths.

This versatility allows manufacturers to serve a broader range of customers and respond more effectively to changing market demands. For example, during a housing boom, manufacturers can adjust their production lines to meet the demand for more building blocks. Conversely, during a landscaping project, the focus can shift to producing specialized paving stones.

3. How Does Automation Benefit Concrete Block Production?

#Speed of Production

Automation accelerates the entire production process. From the mixing of raw materials to the molding, curing, and stacking of concrete blocks, an automatic machine can carry out all these processes much faster than manual labor. This speed means that construction companies can get their building materials on-site quickly, preventing delays and keeping projects on track.

#Reduced Labor Costs

Manual block-making processes require a significant workforce, with people involved in every step of the production process. The automatic concrete block making machine greatly reduces the need for manual labor. This not only reduces labor costs but also decreases the likelihood of human error, improving overall production quality.

#Higher Output with Lower Maintenance

Automatic concrete block making machines are designed to run continuously with minimal maintenance. Their reliability and efficiency mean that production can continue round-the-clock, further increasing the output. The reduced downtime and low-maintenance nature of these machines make them an excellent long-term investment for manufacturers.

4. What Are the Challenges of Using Automatic Concrete Block Making Machines?

While automatic concrete block making machines offer numerous advantages, there are a few challenges to consider:

#Initial Investment Costs

One of the main barriers for smaller companies or new entrants in the construction industry is the initial cost of the machine. The upfront investment can be significant, especially for high-quality, fully automated models. However, the long-term savings and productivity improvements often justify the cost.

#Training and Skilled Operators

Although these machines are designed for ease of use, they still require skilled operators who understand how to manage and maintain them. Operators need to be trained to ensure that the machine functions optimally and that any potential issues are addressed quickly. However, this is a relatively small challenge compared to the benefits provided by the machine.

5. The Future of Automatic Concrete Block Making Machines

As the construction industry continues to evolve, the demand for faster, more efficient, and higher-quality products will only grow. Automatic concrete block making machines will play an increasingly pivotal role in meeting these demands.

With advancements in technology, future models of automatic block making machines will likely be even more energy-efficient, capable of handling a wider variety of products, and equipped with more intelligent automation systems. Additionally, the use of sustainable materials and eco-friendly production methods will become more prominent, aligning with the growing push for greener construction practices.

6. Conclusion: Is the Automatic Concrete Block Making Machine Worth the Investment?

The automatic concrete block making machine is undoubtedly a game-changer in the construction industry. It brings efficiency, cost-effectiveness, and quality control to the production of concrete blocks, paving the way for more sustainable and faster construction processes.

While the initial investment can be high, the long-term benefits of increased productivity, reduced labor costs, and improved product quality make it a valuable asset for any construction company. With the increasing demand for high-quality building materials and the need for faster project completion times, the automatic concrete block making machine is likely to remain an essential tool in the future of construction.