Why Is Anti-Static Flooring Crucial for Your Business and Environment?

2025-01-02

In environments where sensitive electronic equipment, data systems, or precise machinery are in use, even the smallest amount of static electricity can cause major disruptions. This is where anti-static flooring comes into play. But why is anti-static flooring so important, and how can it help protect both your assets and your workforce?

In this blog, we’ll explore the significance of anti-static flooring, how it works, and why it’s essential for certain industries.

What Is Anti-Static Flooring?

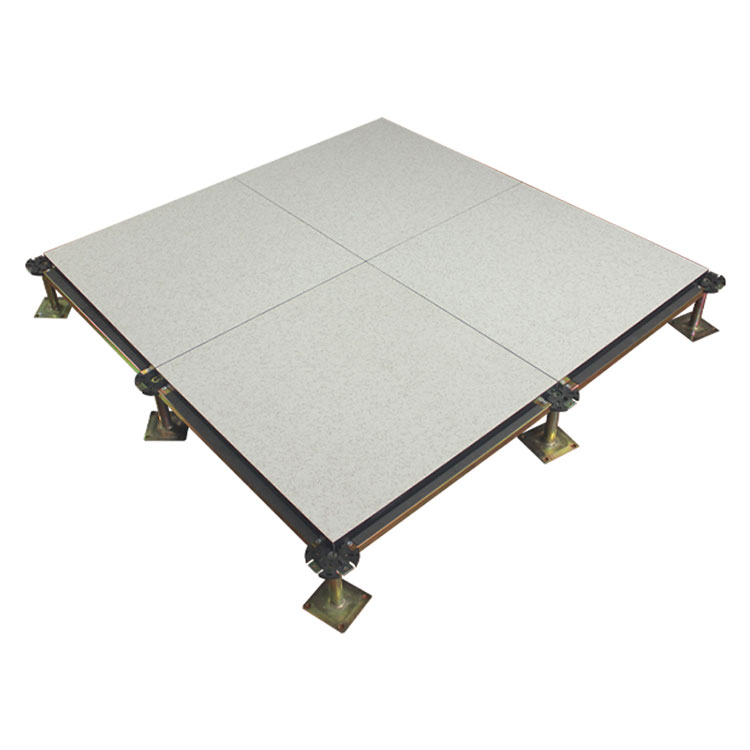

Anti-static flooring is a type of flooring specifically designed to prevent the buildup of static electricity. Static electricity occurs when there is an imbalance of electric charges on the surface of an object, and this imbalance can cause sudden discharges of energy that can damage sensitive equipment or lead to unsafe working conditions.

Anti-static flooring is typically made of materials that either dissipate static charges or prevent their accumulation, ensuring that the environment remains safe from the harmful effects of electrostatic discharge (ESD). This type of flooring is commonly used in areas such as computer rooms, electronics manufacturing plants, clean rooms, and other high-tech environments where precision and safety are paramount.

Why Is Anti-Static Flooring Important?

1. Protecting Sensitive Equipment

One of the most critical reasons for installing anti-static flooring is to protect sensitive electronic equipment. Devices like computers, servers, microchips, and circuit boards are highly susceptible to damage from electrostatic discharge. Even a small static spark can cause irreversible damage, resulting in costly repairs or replacements.

By installing anti-static flooring, businesses can ensure that static charges are safely dissipated into the ground, preventing the buildup of harmful static energy that could jeopardize their equipment and machinery.

2. Preventing Workplace Hazards

In addition to protecting electronics, static electricity poses a significant safety risk in environments dealing with flammable materials or chemicals. A sudden electrostatic discharge can cause a spark, which could potentially ignite volatile gases or liquids. This is especially important in industries like pharmaceuticals, chemicals, and automotive manufacturing.

Anti-static flooring helps reduce the risk of fires or explosions by minimizing the chances of static discharges, providing a safer working environment for employees.

3. Enhancing Product Quality and Reliability

In industries like electronics manufacturing, product quality and reliability are crucial. The integrity of every component—whether it's a motherboard, smartphone, or computer chip—depends on the absence of static interference during production. Anti-static flooring ensures that there is no accidental discharge that could compromise the quality of the final product.

By using anti-static flooring, manufacturers can reduce defects, improve product yield, and ultimately provide customers with higher-quality goods that meet stringent performance standards.

4. Improving Employee Comfort and Safety

While protecting equipment and products is critical, employee comfort and safety should also be a top priority in any workplace. Static electricity buildup can lead to mild but uncomfortable shocks when employees touch metallic objects or interact with machinery. In environments where employees are constantly interacting with electronic devices or machinery, anti-static flooring helps ensure they are not subjected to these disruptive shocks, contributing to a more comfortable and productive working environment.

5. Compliance with Industry Standards

Many industries require specific safety protocols to prevent ESD-related damage. For instance, the electronics and semiconductor industries often require compliance with certain standards like ANSI/ESD S20.20 and IEC 61340, which outline procedures for protecting against electrostatic discharge. Anti-static flooring is one of the most common ways to meet these industry-specific guidelines, ensuring compliance and avoiding potential fines or liabilities.

How Does Anti-Static Flooring Work?

Anti-static flooring is typically constructed from materials that can either conduct or dissipate electrical charges. The flooring works by allowing the static charges that build up on a surface to flow safely into the ground, preventing them from accumulating to hazardous levels.

There are generally two types of anti-static flooring:

- Static-dissipative Flooring: These floors allow static electricity to move slowly from the surface to the ground, reducing the likelihood of a dangerous discharge. They typically have a slightly conductive surface that dissipates charges over time.

- Conductive Flooring: This type of flooring allows static electricity to flow more quickly and directly to the ground. Conductive flooring is typically used in environments where a higher level of protection is needed, such as in high-tech manufacturing areas or clean rooms.

Most anti-static flooring materials, such as vinyl, rubber, or epoxy coatings, are designed with conductive or dissipative properties that ensure the safe removal of static charges from the environment.

Where Is Anti-Static Flooring Used?

Anti-static flooring is used in various industries, including:

1. Electronics Manufacturing

In the electronics manufacturing process, protecting sensitive components like semiconductors, integrated circuits, and displays from static discharge is crucial. Anti-static floors are used in assembly lines, testing areas, and packaging rooms to ensure that products are not damaged by static electricity during production.

2. Data Centers and Server Rooms

Data centers and server rooms house critical infrastructure that requires constant, uninterrupted operation. A single electrostatic discharge can destroy equipment or corrupt data. Anti-static flooring is essential for ensuring the reliability of data servers, networking equipment, and other electronic systems within these facilities.

3. Clean Rooms

In industries such as pharmaceuticals, biotechnology, and aerospace, clean rooms must meet strict cleanliness and contamination control standards. Static electricity can attract dust and particles, which could affect sensitive products or research. Anti-static flooring in clean rooms helps maintain a sterile, particle-free environment.

4. Laboratories and Medical Environments

Laboratories that deal with delicate equipment, including microscopes, diagnostic instruments, and precision measurement devices, benefit from anti-static flooring. Similarly, medical environments where electronic medical devices are used, such as hospitals or clinics, require anti-static flooring to prevent static discharge from harming the equipment or interfering with its function.

5. Automotive Manufacturing

The automotive industry uses electronic components in modern vehicles, and static electricity can cause faults in these systems. Anti-static flooring in automotive manufacturing plants helps protect assembly lines and equipment from the dangers of ESD.

What to Consider When Choosing Anti-Static Flooring

When selecting anti-static flooring for your facility, there are a few key considerations to keep in mind:

- Electrical Resistance: Choose the right level of conductivity or dissipation based on your environment’s needs. Conductive flooring is ideal for areas with high sensitivity to static, while dissipative flooring is sufficient for general use.

- Durability: Anti-static flooring should be durable enough to withstand foot traffic, heavy machinery, and cleaning processes. Materials like vinyl or rubber are often ideal for these environments.

- Maintenance Requirements: Some anti-static floors require regular cleaning and maintenance to maintain their performance. Choose a flooring material that aligns with your maintenance capabilities.

- Compliance: Ensure that the flooring meets industry standards and safety regulations to keep your workplace in compliance with local and international guidelines.

Conclusion

Anti-static flooring is essential in preventing the buildup of static electricity, protecting sensitive equipment, ensuring employee safety, and complying with industry standards. By investing in this type of flooring, businesses can safeguard their assets, improve product quality, and create a safer and more efficient working environment.