Why Are Marine Power Cables Crucial for Safe and Efficient Maritime Operations?

2024-12-13

In the maritime industry, the role of power cables is often overlooked, yet they are essential for the smooth and safe operation of ships, offshore platforms, and other marine structures. Marine power cables are designed to deliver reliable electrical power to various systems on board, ranging from navigation lights to complex machinery. But why exactly are these cables so crucial for maritime operations? In this blog, we’ll explore the importance of marine power cables, their unique design features, and the reasons why they are indispensable for modern shipping and offshore operations.

What Are Marine Power Cables?

Marine power cables are specially designed cables used for transmitting electrical power on ships, offshore rigs, and other marine environments. Unlike standard power cables, marine power cables are built to withstand the harsh conditions at sea, including saltwater exposure, high humidity, and temperature fluctuations. They are typically used to connect power sources, such as generators or power distribution boards, to electrical equipment on ships, offshore platforms, and other maritime installations.

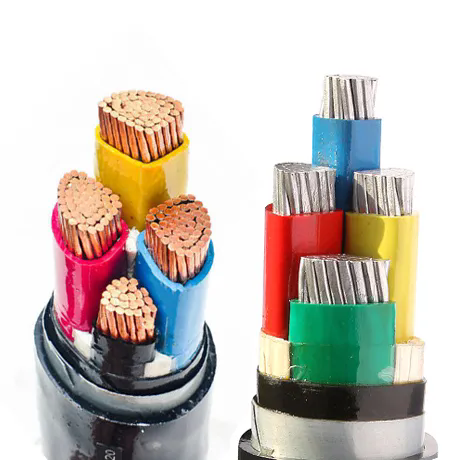

These cables are made from high-quality materials like copper or aluminum for conductors, and they are usually insulated with durable materials such as rubber, PVC, or thermoplastic compounds to protect them from environmental damage.

Why Are Marine Power Cables Essential for Maritime Operations?

1. Safety and Reliability

The most important role of marine power cables is to ensure the safety and reliability of onboard electrical systems. Without a constant and dependable power supply, critical systems such as navigation equipment, communication tools, and lighting would fail, jeopardizing the vessel's operations and the safety of those aboard.

Marine cables are engineered to prevent failures that could lead to power loss. The cables are designed to be robust enough to resist impacts, corrosion, and mechanical stress, ensuring that essential systems remain functional even in challenging marine conditions.

2. Durability in Harsh Conditions

The marine environment presents numerous challenges for electrical components, and power cables are no exception. Saltwater corrosion, UV exposure, and extreme temperatures can quickly degrade regular cables, causing failures that disrupt operations. Marine power cables are specifically designed to endure these harsh conditions. Their insulation is specially formulated to resist corrosion from saltwater, making them suitable for prolonged exposure to wet and salty environments.

Additionally, marine power cables are often designed to be resistant to fire, oil, and chemicals, providing extra protection in case of accidental exposure to hazardous substances.

3. Energy Efficiency

Marine vessels and offshore platforms rely heavily on power systems to operate essential equipment like pumps, compressors, heating, ventilation, and air conditioning (HVAC) systems. To ensure the efficient transfer of power, marine power cables are designed to minimize energy losses. Their high conductivity and low resistance help optimize energy efficiency, ensuring that the power generated by onboard generators is delivered effectively to all connected systems.

This energy efficiency is especially crucial for large ships and offshore rigs, where power demands are high, and energy conservation is essential for both operational performance and environmental sustainability.

4. Customization for Various Applications

Marine power cables are not a one-size-fits-all solution; they are highly customizable to meet specific requirements based on the application. For instance, cables used in a commercial shipping vessel might have different specifications from those used in an offshore oil platform. Factors such as voltage ratings, size, and flexibility all vary based on the electrical demands of the specific maritime installation.

Furthermore, marine power cables come in different constructions to accommodate varying installation needs. They may include single-core or multi-core designs, and be suitable for use in either stationary or moving applications. Flexible cables are often used for equipment that requires frequent movement, while rigid cables are preferred for fixed installations.

5. Conformance to International Standards

Marine power cables must comply with stringent international standards to ensure their safety, performance, and compatibility across different maritime regions. Regulatory bodies such as the International Maritime Organization (IMO), as well as classification societies like Lloyd's Register (LR) and the American Bureau of Shipping (ABS), have established regulations for the construction and installation of marine cables. These standards ensure that the cables are safe to use in maritime environments and meet all necessary requirements for shipbuilders, owners, and operators.

In addition, marine cables are often tested for their fire resistance, durability, and environmental performance, offering peace of mind for maritime operators and complying with safety regulations.

Applications of Marine Power Cables

Marine power cables are widely used in various maritime applications, including:

1. Commercial Ships

Large commercial vessels, such as container ships, tankers, and cruise ships, rely on marine power cables for the operation of essential equipment. From powering the engine systems to providing electricity for lighting, entertainment, and HVAC systems, these cables ensure that vessels can operate efficiently and safely during their voyages.

2. Offshore Oil and Gas Platforms

Offshore oil rigs and gas platforms operate in challenging environments, often located far from the shore. Marine power cables are used to supply power to various equipment, such as drilling rigs, compressors, and safety systems. In these high-risk settings, the reliability and durability of the cables are paramount to maintaining safety and efficiency.

3. Naval and Military Vessels

Naval ships and military vessels depend on marine power cables to run critical systems such as communication, radar, navigation, and weaponry. These cables must be particularly durable and capable of withstanding extreme conditions, including vibrations, impacts, and heavy loads.

4. Renewable Energy Installations

With the increasing demand for renewable energy sources, marine power cables are also being used to connect offshore wind farms to the grid. These cables are essential for transmitting the electricity generated by wind turbines to land-based power stations, ensuring the efficient distribution of renewable energy.

Conclusion

Marine power cables are an indispensable part of modern maritime operations. They provide a reliable and safe power supply to various electrical systems on ships, offshore platforms, and other marine structures. Their design and construction make them resistant to harsh environmental conditions, ensuring that vessels and installations can operate efficiently and safely. Whether it's for commercial shipping, offshore oil drilling, military operations, or renewable energy installations, marine power cables are vital for powering the modern maritime industry.

As the maritime sector continues to evolve with new technologies and innovations, the demand for advanced marine power cables will only grow. Ensuring that these cables meet the highest standards of performance, durability, and safety will continue to be a key focus in keeping the industry running smoothly.