What Is a Galvanometer Laser Control Board and Why Is It Essential in Laser Systems?

2025-06-24

A Galvanometer Laser Control Board plays a pivotal role in modern laser systems, especially those requiring high-speed and high-precision beam positioning. This advanced control unit works in tandem with galvanometer scanners to direct laser beams accurately for tasks such as engraving, marking, welding, and cutting. But what exactly does this control board do, and why is it so crucial?

What Is a Galvanometer Laser Control Board?

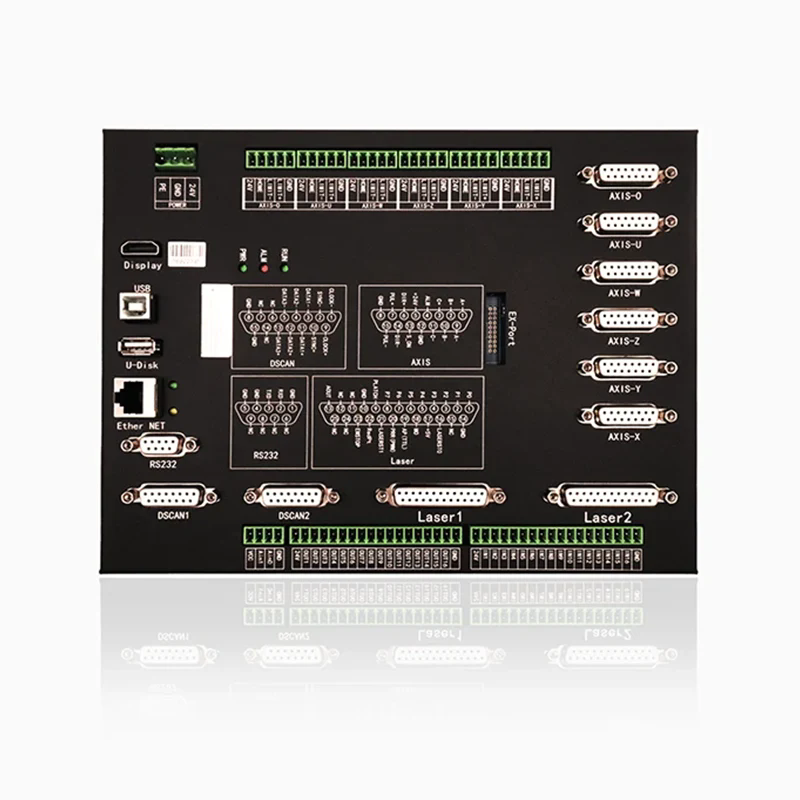

A Galvanometer Laser Control Board is an electronic device designed to interface between a laser control software and galvanometer (galvo) scanning heads. It sends digital or analog signals that control the angular position of mirrors inside the galvo scanner. These mirrors reflect the laser beam, enabling it to be steered with extreme precision across the working surface.

The control board interprets vector data or G-code from design software and converts it into coordinated movements of the galvo motors. In essence, the board is the brain behind the beam’s movement.

How Does It Work in Laser Applications?

In a typical laser marking or cutting system, the control software first generates a pattern or path for the laser. The Galvanometer Laser Control Board receives this data and translates it into real-time instructions for the X and Y axis galvanometers. As the galvo motors adjust the mirror angles, the laser beam follows the desired path with high accuracy and speed.

The control board also manages synchronization between the laser power output and beam positioning, ensuring precise exposure times for consistent results.

What Are the Key Features?

Modern Galvanometer Laser Control Boards come with a range of advanced features, including:

High-speed data processing: Enables real-time control of fast-moving beams.

USB, Ethernet, or PCI interfaces: Allows seamless connection with computers or industrial controllers.

Support for multiple laser types: Compatible with fiber lasers and UV lasers.

Real-time feedback systems: Ensures better accuracy and error correction during operation.

User-friendly software compatibility: Works with various design and marking platforms.

Why Is It Critical for Laser Precision?

The accuracy and repeatability of laser systems heavily depend on the performance of the control board. A high-quality Galvanometer Laser Control Board ensures:

Precise beam placement, essential for fine details in engraving and micro-cutting.

High-speed operation, improving production efficiency.

Reduced system drift or distortion, leading to more consistent output.

Smooth motion trajectories, minimizing sharp transitions and defects.

What Should You Consider When Choosing One?

When selecting a Galvanometer Laser Control Board, consider the following:

Compatibility with your laser type and scanner head

Control resolution and speed

Software support and ease of integration

Connectivity options and firmware upgradability

Technical support and documentation

Conclusion

The Galvanometer Laser Control Board is a foundational component in any laser system that demands high precision and speed. It bridges the gap between design software and mechanical movement, ensuring your laser performs at its best. Whether for industrial marking or precision cutting, investing in a quality control board is essential for achieving optimal results.