The Benefits of a 3D Steel Welding Table for Precision Fabrication

2024-09-14

In the world of metal fabrication and welding, precision is everything. The use of a 3D steel welding table is becoming increasingly popular as it provides an essential platform for welders and fabricators to achieve high levels of accuracy and efficiency. Designed with a modular system of adjustable and interchangeable components, a 3D welding table offers numerous advantages for both professionals and hobbyists.

What is a 3D Steel Welding Table?

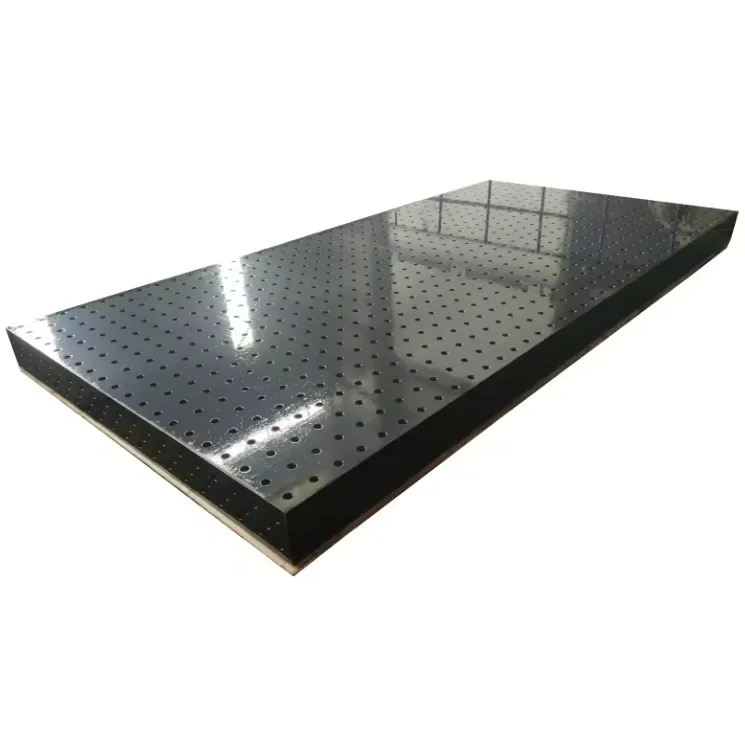

A 3D steel welding table is a heavy-duty, flat work surface made from high-quality steel, equipped with a grid or matrix of holes. These holes allow for the attachment of clamps, fixtures, and other tools, giving welders the ability to position their workpieces with extreme accuracy. The "3D" in the name refers to the table’s capability to support workpieces at different angles, making it versatile for a variety of welding and fabrication tasks.

Key Features of 3D Steel Welding Tables

1. Precision and Accuracy

One of the standout features of a 3D welding table is its ability to provide precise positioning for workpieces. The grid of holes, typically spaced evenly across the surface, allows for the use of clamps and fixtures that hold materials securely in place. This ensures that components remain perfectly aligned during welding or assembly, reducing the likelihood of errors and rework.

2. Modular Design

The modular design of 3D welding tables allows for the customization of the workspace. With interchangeable components like clamps, stops, and angles, welders can easily configure the table to suit the specific needs of their project. This flexibility is especially useful for complex projects that involve multi-angle welding or fabricating large, irregularly shaped workpieces.

3. Heavy-Duty Construction

These tables are made from high-quality steel, often with a plasma-nitrided surface for additional durability and resistance to corrosion. The robust construction ensures that the table can support heavy materials and withstand the rigors of daily use in an industrial or workshop environment. The strength and stability provided by a 3D steel welding table contribute to higher-quality welds and longer-lasting equipment.

4. Versatility

3D welding tables are suitable for a wide range of tasks, including metal fabrication, welding, assembly, and machining. Whether working with small components or large structures, the versatility of a 3D table allows for easy adjustment to accommodate various project sizes and types. The table’s adjustable nature also enables welders to perform complex angle welds with ease.

5. Time-Saving and Efficiency

The ability to securely hold materials in place and quickly reposition workpieces on a 3D steel welding table leads to increased efficiency. Welders can reduce setup times and make faster adjustments to their work, improving workflow and productivity. The precision of the table also minimizes mistakes, which reduces the time spent on corrections or rework.

6. Ergonomics and Safety

Working on a 3D welding table can improve both the ergonomics and safety of welding tasks. The ability to adjust the height and angle of the table means that welders can position their workpieces at a comfortable working level, reducing strain and fatigue. Additionally, the secure clamping system prevents workpieces from moving during welding, which enhances safety by minimizing the risk of accidents.

Applications of 3D Steel Welding Tables

3D steel welding tables are used in a variety of industries, including:

- Automotive and Aerospace: For precision welding and assembly of vehicle frames, components, and prototypes.

- Metal Fabrication: Used in workshops for creating metal structures, parts, and machinery with high accuracy.

- Construction: Ideal for fabricating building components such as beams, frames, and support structures.

- Art and Sculpture: Artists and sculptors use 3D welding tables to create intricate metal designs that require precise positioning and alignment.

Conclusion

The 3D steel welding table is an invaluable tool for any professional or hobbyist welder who demands precision, flexibility, and efficiency in their work. Its robust construction, modular design, and ability to handle complex welding tasks make it a go-to solution for industries ranging from automotive and aerospace to construction and metal fabrication.

With a 3D welding table, welders can enhance their productivity, improve their welding quality, and take on more intricate projects with confidence. Whether you're welding small parts or assembling large metal structures, the 3D steel welding table ensures that your work is done accurately and efficiently.