The Advantages of ESD PEEK Sheets: A Game Changer in Electronics Manufacturing

2024-10-08

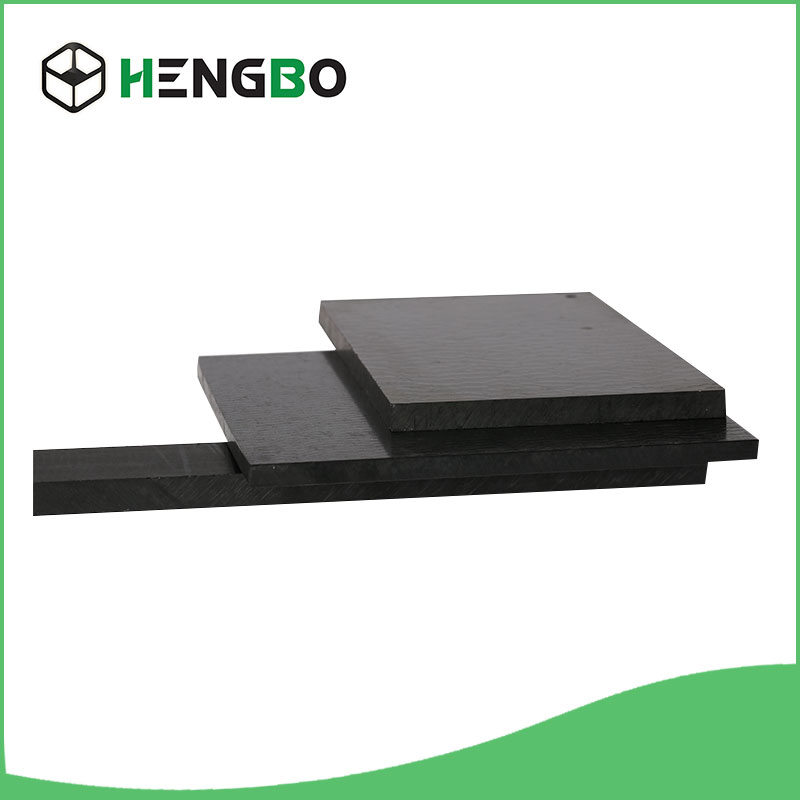

In today’s fast-paced technological landscape, the demand for reliable materials in electronics manufacturing is greater than ever. One material that has gained significant attention for its exceptional properties is ESD PEEK (Electrostatic Discharge Polyether Ether Ketone) sheet. Known for its excellent mechanical, thermal, and electrical properties, ESD PEEK sheets are revolutionizing the way manufacturers approach electronic components and devices. In this blog, we’ll delve into what ESD PEEK sheets are, their unique advantages, applications, and considerations for use.

What is ESD PEEK?

ESD PEEK is a specialized type of polyether ether ketone that has been engineered to provide electrostatic discharge (ESD) protection. This thermoplastic polymer combines the inherent strength and thermal stability of PEEK with the added feature of ESD conductivity. The material is often used in environments where static electricity can pose risks, such as in electronics manufacturing, semiconductor fabrication, and aerospace industries.

Key Advantages of ESD PEEK Sheets

1. Electrostatic Discharge Protection: The primary benefit of ESD PEEK sheets is their ability to prevent electrostatic discharge, which can damage sensitive electronic components. This makes them an ideal choice for applications in cleanrooms and other static-sensitive environments.

2. High Mechanical Strength: ESD PEEK sheets are known for their impressive mechanical strength and rigidity. This makes them suitable for structural components that require durability and resistance to wear and tear.

3. Thermal Stability: With a high melting point (approximately 343°C or 650°F), ESD PEEK sheets can withstand elevated temperatures without deforming. This characteristic is crucial in industries where components may be exposed to high heat during processing or operation.

4. Chemical Resistance: ESD PEEK is resistant to a wide range of chemicals, including solvents, acids, and bases. This resistance ensures longevity and reliability, especially in harsh manufacturing environments.

5. Low Moisture Absorption: The low moisture absorption of ESD PEEK sheets helps maintain dimensional stability, making them reliable in various humidity conditions. This property is especially important for applications in cleanrooms.

6. Easy Machinability: ESD PEEK sheets can be easily machined and fabricated into intricate shapes and components. This versatility allows manufacturers to create custom parts tailored to specific needs.

Applications of ESD PEEK Sheets

ESD PEEK sheets find applications across various industries due to their exceptional properties:

1. Electronics Manufacturing: Used for components such as trays, fixtures, and covers that protect sensitive electronic parts from static discharge.

2. Semiconductor Industry: ESD PEEK sheets are utilized in wafer handling, assembly, and transport, providing safe environments for delicate semiconductor devices.

3. Aerospace: In the aerospace industry, ESD PEEK sheets are employed in the production of components that require both mechanical strength and ESD protection.

4. Medical Devices: ESD PEEK is increasingly being used in the manufacturing of medical devices, where both reliability and cleanliness are critical.

5. Automotive Industry: In automotive applications, ESD PEEK sheets are used for electrical insulation and structural components that must endure harsh operating conditions.

Considerations for Using ESD PEEK Sheets

1. Cost: While ESD PEEK sheets offer numerous advantages, they can be more expensive than traditional materials. It’s essential to weigh the benefits against the cost for specific applications.

2. Processing Conditions: When working with ESD PEEK, be mindful of processing temperatures and conditions, as the material may require specialized equipment for machining and fabrication.

3. Supplier Quality: Ensure that you source ESD PEEK sheets from reputable suppliers who provide high-quality materials that meet industry standards.

Conclusion

ESD PEEK sheets are an innovative solution for manufacturers seeking to enhance the reliability and performance of their electronic components. With their unique combination of electrostatic discharge protection, high mechanical strength, thermal stability, and chemical resistance, these sheets are paving the way for advancements in various industries.

As technology continues to evolve, the need for reliable materials like ESD PEEK will only grow. By incorporating ESD PEEK sheets into your manufacturing processes, you can ensure the safety and longevity of your electronic products, making them an invaluable addition to any production line. Whether you're in electronics, aerospace, or medical device manufacturing, consider ESD PEEK sheets as a robust solution to meet your material needs.