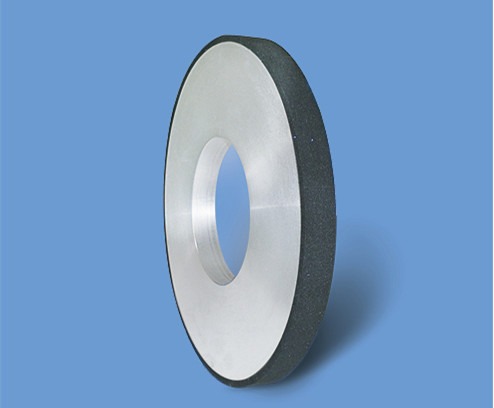

Key points regarding Parallel Grinding Wheel

2023-11-14

The term "parallel grinding wheel" typically refers to a type of grinding wheel that is designed for parallel grinding operations. Here are some key points regarding parallel grinding wheels:

1. Design and Function:

- Parallel Grinding: These wheels are specifically designed for applications where the grinding operation involves creating parallel surfaces or achieving parallelism in the workpiece.

- Parallel Grinding Operations: This type of wheel is commonly used in surface grinding and other processes where maintaining parallelism between the grinding wheel and the workpiece is critical.

2. Wheel Types:

- Various Types: Parallel grinding wheels can come in various types, including but not limited to, bonded abrasive wheels (such as vitrified or resin-bonded wheels), electroplated diamond wheels, or other specialized designs.

- Diamond or Abrasive Grits: Depending on the application, these wheels may feature diamond grits or other abrasive materials suitable for the specific materials being ground.

3. Applications:

- Surface Grinding: Parallel grinding wheels are often employed in surface grinding applications where achieving flatness and parallelism is essential.

- Precision Machining: They are commonly used in precision machining operations where tight tolerances on parallelism are required.

- Metalworking and Toolmaking: Applications can include metalworking, tool and die making, and other industries where precise parallel grinding is crucial.

4. Grit Size and Material Compatibility:

- Grit Size Selection: The choice of grit size depends on the material being ground and the desired surface finish. Finer grits are used for finishing operations, while coarser grits are employed for material removal.

- Material Compatibility: The selection of the grinding wheel should consider the hardness and composition of the workpiece material to ensure effective grinding.

5. Cooling and Lubrication:

- Cooling Systems: Depending on the application, parallel grinding operations may benefit from the use of cooling or lubrication systems to prevent overheating of the workpiece and the grinding wheel.

6. Safety Precautions:

- Proper Use of PPE: As with any grinding operation, operators should use appropriate personal protective equipment (PPE), including safety glasses, face shields, and gloves.

- Machine Guards: Ensuring that the grinding machine has proper guards in place is essential for operator safety.

7. Selection Considerations:

- Workpiece Material: Consider the type of material being ground and choose a wheel with the appropriate characteristics for effective grinding.

- Surface Finish Requirements: The required surface finish and level of precision will influence the choice of the parallel grinding wheel.

It's crucial to follow the manufacturer's guidelines and recommendations for the specific type of parallel grinding wheel being used, as specifications may vary depending on the wheel's design and intended applications.