Here's a breakdown of the key components and features of a 2-platen injection molding machine

2023-12-05

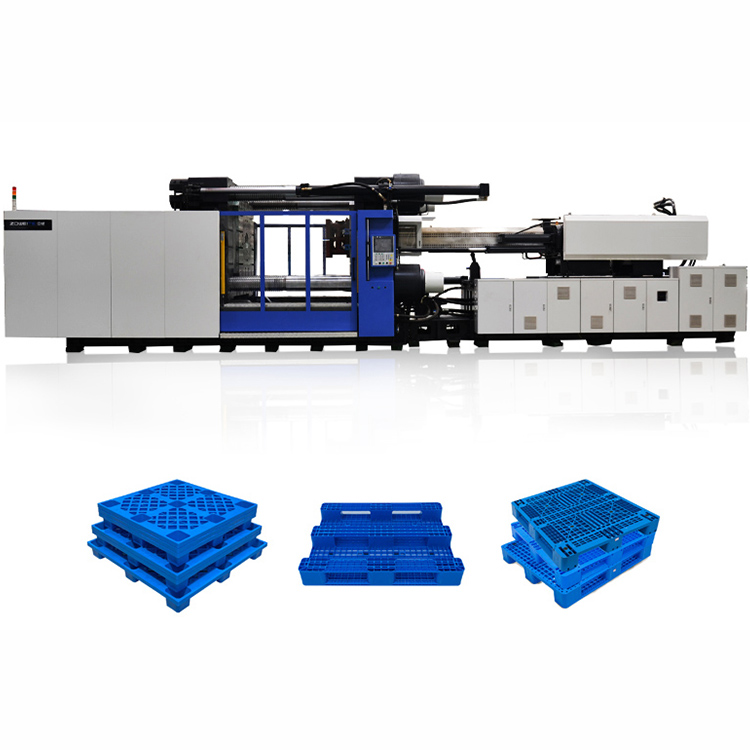

A 2-platen injection molding machine is a type of injection molding machine that consists of two platens or large plates used to hold the mold halves together during the injection molding process. Injection molding is a manufacturing process for producing parts by injecting molten material into a mold, where it solidifies and takes the shape of the mold cavity.

Here's a breakdown of the key components and features of a 2-platen injection molding machine:

1. Two Platens:

- The machine has two large platens that hold the mold. One platen is stationary, while the other is movable. The mold is clamped between these two platens during the injection process.

2. Clamping Unit:

- The clamping unit consists of the two platens and the mechanism that moves one of the platens to close and open the mold. This unit provides the force needed to keep the mold closed during injection and cooling.

3. Injection Unit:

- The injection unit is responsible for melting and injecting the plastic material into the mold. It includes a barrel, screw, and motor for plasticizing and injecting the material into the mold cavity.

4. Hydraulic System:

- 2-platen injection molding machines typically use hydraulic systems to provide the necessary force for clamping and injection. The hydraulic system controls the movement of the platens and other machine functions.

5. Controller:

- An electronic controller manages and coordinates the various functions of the injection molding machine. It controls parameters such as injection pressure, temperature, and cycle time.

6. Mold:

- The mold is a crucial part of the process, as it defines the shape and features of the final product. It is designed with two halves that come together during the clamping process.

7. Cooling System:

- After the molten material is injected into the mold and takes its shape, it needs to cool and solidify. The machine is equipped with a cooling system to expedite this process.

2-platen injection molding machines are known for their efficiency, reliability, and the ability to accommodate larger molds. The two-platen design allows for more significant mold opening strokes, making it suitable for molding larger parts. These machines are commonly used in various industries for producing a wide range of plastic products.