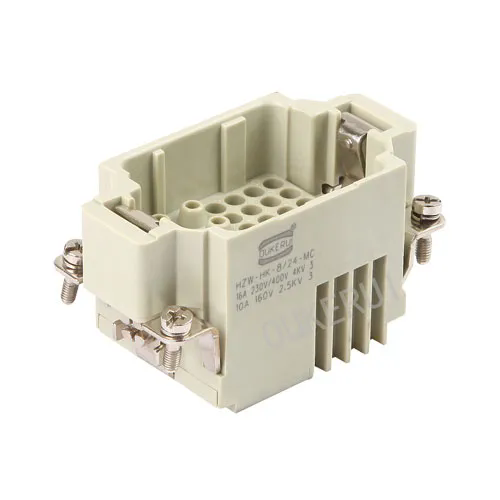

Heavy Duty Connector Inserts: Ensuring Reliable Connections in Challenging Environments

2024-08-14

In industrial and demanding applications, maintaining reliable electrical connections is crucial for operational efficiency and safety. Heavy duty connector inserts play a key role in ensuring that electrical connections withstand harsh conditions and provide consistent performance. This blog will explore the features, benefits, and applications of heavy duty connector inserts, and why they are essential for robust and reliable connections.

What Are Heavy Duty Connector Inserts?

Heavy duty connector inserts are specialized components used within electrical connectors to facilitate secure and reliable connections in challenging environments. They are designed to be inserted into a connector housing, providing the necessary interface for electrical contacts to establish a connection. These inserts are typically used in conjunction with heavy duty connectors, which are built to handle high currents, voltages, and rugged conditions.

Key Features of Heavy Duty Connector Inserts

1. Durability:

Heavy duty connector inserts are constructed from robust materials such as high-grade plastics, metals, or composites. These materials are chosen for their ability to withstand mechanical stress, corrosion, and temperature extremes.

2. High Electrical Performance:

The inserts are designed to handle high electrical loads and provide consistent performance. They are engineered to ensure minimal contact resistance and reliable conductivity.

3. Environmental Resistance:

These inserts are often designed to resist environmental factors such as moisture, dust, and chemicals. They may feature sealing mechanisms, such as O-rings or gaskets, to protect the connection from contaminants.

4. Precision Engineering:

Heavy duty connector inserts are manufactured with high precision to ensure accurate alignment and secure connections. This precision helps prevent issues such as loose connections or electrical arcing.

5. Versatility:

These inserts come in various configurations and sizes to accommodate different types of connectors and applications. They can be designed for various pin counts, contact arrangements, and connection types.

6. Ease of Maintenance:

Many heavy duty connector inserts are designed for ease of replacement and maintenance. This allows for quick and straightforward servicing without the need for extensive disassembly.

Benefits of Heavy Duty Connector Inserts

1. Enhanced Reliability:

By providing a secure and stable connection, heavy duty connector inserts help ensure reliable electrical performance. This reduces the risk of connection failures and improves overall system reliability.

2. Increased Longevity:

The durable materials and design features of heavy duty connector inserts contribute to their long lifespan. They are built to withstand harsh conditions, reducing the need for frequent replacements.

3. Improved Safety:

Reliable and secure connections are critical for safety in electrical systems. Heavy duty connector inserts help prevent issues such as electrical shorts, overheating, and arcing, which can pose safety hazards.

4. Reduced Downtime:

By ensuring reliable connections and facilitating easy maintenance, heavy duty connector inserts help minimize system downtime. This leads to improved operational efficiency and reduced maintenance costs.

5. Adaptability:

The versatility of heavy duty connector inserts allows them to be used in a wide range of applications and environments. They can be tailored to meet specific requirements and integrate with various connector housings.

Applications of Heavy Duty Connector Inserts

1. Industrial Automation:

Heavy duty connector inserts are commonly used in industrial automation systems to connect machinery, control systems, and sensors. Their durability and performance are essential for maintaining reliable operation in industrial environments.

2. Automotive Industry:

In the automotive industry, these inserts are used in vehicles to connect electrical systems, including engine controls, lighting, and infotainment systems. Their resistance to vibrations and environmental factors makes them ideal for automotive applications.

3. Aerospace:

Aerospace applications require connectors that can withstand extreme conditions, including temperature fluctuations and vibrations. Heavy duty connector inserts are used in aerospace systems to ensure reliable connections in critical systems.

4. Military and Defense:

Military and defense applications often involve harsh and demanding environments. Heavy duty connector inserts are used in military equipment and systems to provide secure and reliable connections under challenging conditions.

5. Marine:

In marine applications, connectors are exposed to moisture, salt, and other corrosive elements. Heavy duty connector inserts are designed to resist these conditions and maintain reliable connections in marine environments.

6. Power Generation and Distribution:

Heavy duty connector inserts are used in power generation and distribution systems to connect high-voltage equipment and control systems. Their ability to handle high currents and resist environmental factors is critical for power infrastructure.

Choosing the Right Heavy Duty Connector Insert

1. Identify Requirements:

Determine the electrical and environmental requirements of your application. Consider factors such as voltage, current, temperature, and exposure to contaminants.

2. Select Material:

Choose an insert material that matches the environmental conditions and performance requirements of your application. Materials such as high-grade plastics, metals, or composites offer different benefits.

3. Consider Connector Configuration:

Ensure that the insert is compatible with the connector housing and pin configuration. Verify that it meets the necessary specifications for pin count and contact arrangement.

4. Check for Certifications:

Look for inserts that meet industry standards and certifications, such as IEC, UL, or MIL-SPEC, to ensure quality and compliance with safety regulations.

In Conclusion

Heavy duty connector inserts are crucial components for ensuring reliable electrical connections in demanding and harsh environments. Their durability, high performance, and versatility make them essential for applications across various industries, including industrial automation, automotive, aerospace, and more.

By understanding the key features, benefits, and applications of heavy duty connector inserts, you can make informed decisions when selecting connectors for your specific needs. Investing in high-quality inserts helps ensure the reliability and safety of your electrical systems, ultimately contributing to improved operational efficiency and reduced downtime.