Functions of Wind Power Flanges

2024-07-05

A wind power flange is a specialized component used in the construction and assembly of wind turbines. It plays a crucial role in connecting different sections of the turbine structure, such as tower sections, nacelles, and blades, while also providing support and ensuring structural integrity. Here's an overview of wind power flanges, their functions, types, and considerations:

Functions of Wind Power Flanges

1. Connection and Assembly:

- Wind power flanges facilitate the connection between various components of a wind turbine, including tower sections, nacelles (housing the generator and gearbox), and blades.

2. Load Bearing:

- They bear the loads and forces exerted on the turbine structure, including wind loads, gravitational forces, and operational stresses.

3. Sealing and Alignment:

- Flanges ensure proper alignment of turbine components during assembly and operation, maintaining efficiency and reliability.

4. Safety and Stability:

- They contribute to the overall stability and safety of the wind turbine by securely holding components in place and preventing structural deformation.

Types of Wind Power Flanges

1. Tower Flanges:

- Used to connect individual tower sections in multi-section wind turbine towers. They are designed to withstand the vertical loads and torsional forces exerted by the tower structure.

2. Nacelle Flanges:

- Connect the nacelle to the tower or the main frame of the wind turbine. These flanges support the weight of the nacelle and the rotating components within it.

3. Blade Flanges:

- Connect wind turbine blades to the hub. Blade flanges must handle both static and dynamic loads from wind forces and provide a secure attachment point for the blades.

Considerations for Wind Power Flanges

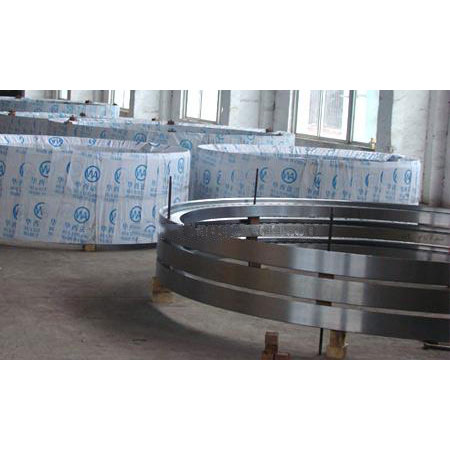

- Material Selection: Flanges are typically made from high-strength steel alloys that can withstand the mechanical stresses and environmental conditions specific to wind turbine applications.

- Design Standards: Flanges must comply with industry standards and regulations, ensuring they meet performance, safety, and reliability requirements.

- Corrosion Resistance: Given the outdoor exposure of wind turbines, flanges may require protective coatings or materials to resist corrosion and extend service life.

- Fatigue Resistance: Flanges must be designed to withstand cyclic loading and fatigue caused by wind-induced vibrations and operational cycles.

- Installation and Maintenance: Proper installation procedures and regular maintenance are crucial to ensuring flanges perform effectively over the turbine's operational lifetime.

Applications of Wind Power Flanges

- Onshore and Offshore Wind Farms: Used in both onshore and offshore wind turbines to support tower structures, nacelles, and blades.

- Turbine Upgrades and Maintenance: Flanges may be replaced or upgraded during turbine maintenance and refurbishment to improve performance and reliability.

- New Turbine Installations: Essential components in the construction of new wind turbines, supporting the growth of renewable energy infrastructure.

Wind power flanges are integral components in the construction, operation, and maintenance of wind turbines, contributing to the efficiency, reliability, and safety of renewable energy generation from wind power. Their robust design and performance capabilities ensure the structural integrity and operational success of wind turbine systems in various environmental conditions.