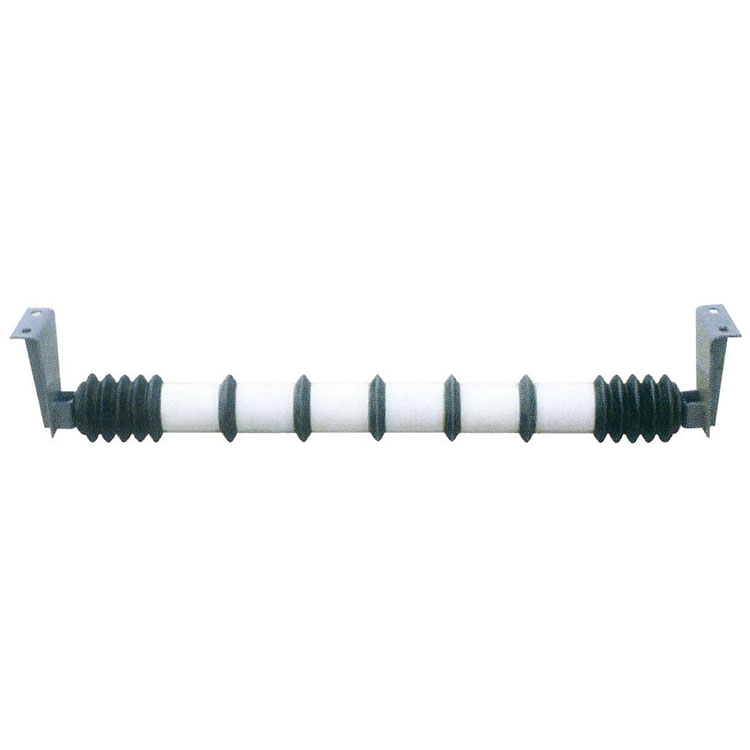

Functions of a Parallel Comb Idlers

2024-07-17

The functions of a parallel comb idler in conveyor systems are essential for maintaining efficient and reliable operations. Here’s a detailed look at its primary functions:

1. Alignment

- Preventing Belt Mistracking: The parallel comb idler helps keep the conveyor belt centered on the rollers, preventing it from drifting sideways. This ensures the belt stays aligned with the conveyor structure.

- Stability: By maintaining alignment, the idler prevents lateral movements that can cause the belt to run off track, reducing the risk of damage to the belt and the conveyor system.

2. Support

- Reducing Sagging: The idler provides additional support to the conveyor belt, particularly in areas where the belt might otherwise sag under the weight of the transported materials.

- Enhanced Durability: Proper support helps distribute the load evenly, reducing stress and wear on the belt, thus extending its lifespan.

3. Load Distribution

- Even Load Distribution: The parallel comb idler ensures that the weight of the transported material is evenly distributed across the width of the belt. This prevents localized wear and tear and reduces the risk of belt failure.

- Efficient Operation: By distributing the load evenly, the idler contributes to more efficient and smoother operation of the conveyor system, reducing downtime and maintenance needs.

4. Cleaning

- Debris Removal: The comb-like design of the idler helps to remove debris and other materials that may stick to the belt. This prevents material buildup that could cause belt misalignment or damage.

- Maintaining Cleanliness: By keeping the belt clean, the idler reduces the need for frequent manual cleaning, thereby saving time and labor costs.

5. Reducing Maintenance

- Less Wear and Tear: By ensuring proper alignment, support, and load distribution, the idler minimizes wear and tear on the conveyor belt and other components, reducing the frequency of maintenance and repair.

- Longevity: Extends the life of the conveyor belt and other system components by maintaining optimal operating conditions.

Summary

Parallel comb idlers are critical components in conveyor systems, ensuring proper alignment, support, load distribution, and cleanliness of the conveyor belt. They enhance the overall efficiency, reliability, and longevity of the system, making them indispensable in various industries such as mining, manufacturing, agriculture, and logistics.