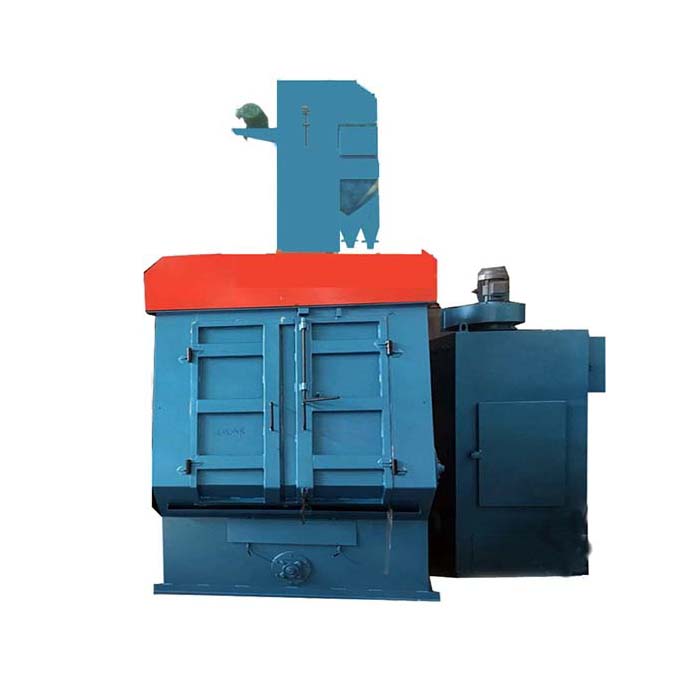

Functions and Benefits of Water-tap Shot Blasting Machine

2024-07-23

A water-tap shot blasting machine, often referred to as a water-cooled shot blasting machine, is a specialized equipment used for surface preparation and cleaning in various industrial applications. Here’s a detailed overview of its features, functions, and benefits:

Key Features:

1. Shot Blasting Mechanism:

- Abrasive Media: Uses abrasive materials, such as steel shots or grit, to clean and prepare surfaces.

- Blast Wheels: Equipped with rotating blast wheels that propel the abrasive media onto the surface.

2. Water Cooling System:

- Cooling Mechanism: Incorporates a water cooling system to cool the blast wheels and other components during operation, preventing overheating and extending equipment life.

- Water Tap Function: Utilizes a tap or similar water source to maintain the cooling system.

3. Cabinet and Housing:

- Protective Cabinet: Enclosed cabinet to contain the blasting process and protect the operator from the abrasive media and dust.

- Durable Construction: Made from materials resistant to abrasion and corrosion.

4. Control Systems:

- Adjustable Settings: Allows operators to adjust the blast intensity, duration, and angle.

- Automated Controls: Often features automated controls for precise operation and efficiency.

5. Filtration and Recycling:

- Dust Extraction: Includes dust collection systems to remove and filter airborne particles.

- Media Recycling: Some models include systems for recycling and reusing the abrasive media.

Functions:

1. Surface Preparation:

- Cleaning: Removes rust, scale, old coatings, and contaminants from metal surfaces to prepare them for painting, coating, or further processing.

- Profiling: Creates a rough surface profile to enhance adhesion of subsequent coatings.

2. Surface Finishing:

- Polishing: Can be used to achieve a smooth, polished finish on metal surfaces.

- Smoothing: Helps in smoothing out imperfections and irregularities.

3. Maintenance and Repair:

- Restoration: Used in the maintenance and repair of metal components, such as machinery parts and structures.

Benefits:

1. Efficiency:

- Fast Operation: Provides a quick and efficient method for cleaning and preparing large surfaces compared to manual methods.

- Consistent Results: Ensures uniform surface preparation and cleaning across various parts.

2. Durability:

- Robust Construction: Built to withstand the harsh conditions of shot blasting and high-impact operations.

- Extended Equipment Life: Water cooling helps to prevent overheating and extend the lifespan of critical components.

3. Safety:

- Contained Process: Enclosed cabinet reduces the risk of operator exposure to abrasive media and dust.

- Controlled Environment: Maintains a controlled blasting environment to improve safety and efficiency.

4. Environmental Considerations:

- Dust Control: Dust extraction systems help to reduce environmental contamination.

- Media Recycling: Recycles abrasive media, reducing waste and operating costs.

Applications:

1. Industrial Manufacturing:

- Metal Fabrication: Prepares metal parts and components for further processing or coating.

- Automotive Industry: Cleans and prepares automotive parts for painting or coating.

2. Construction and Maintenance:

- Structural Steel: Prepares structural steel components for coatings and painting.

- Pipeline Maintenance: Cleans pipelines and other infrastructure components.

3. Aerospace and Defense:

- Component Cleaning: Used in the aerospace and defense industries to clean and prepare critical components.

Maintenance Tips:

1. Regular Inspection:

- Check Components: Inspect the blast wheels, nozzles, and other critical components for wear and damage.

- Monitor Cooling System: Ensure that the water cooling system is functioning properly and that there are no leaks.

2. Cleaning:

- Remove Debris: Regularly clean the interior of the cabinet and remove any accumulated abrasive media and dust.

- Filter Maintenance: Clean or replace filters in the dust extraction system as needed.

3. Lubrication:

- Grease Moving Parts: Lubricate moving parts, such as blast wheels and bearings, to ensure smooth operation and prevent wear.

Conclusion:

The water-tap shot blasting machine is an essential tool for efficient and effective surface preparation and cleaning in various industrial settings. Its advanced features, including water cooling and automated controls, enhance performance and durability, while providing consistent and reliable results. Regular maintenance and proper operation ensure the longevity and effectiveness of the equipment.