Features of Purification and Recovery Unit

2024-06-28

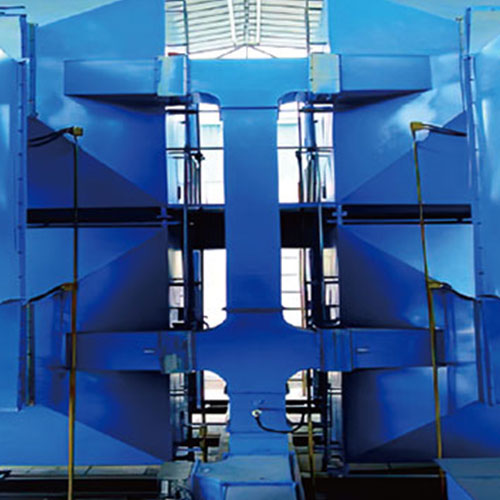

A purification and recovery unit typically refers to a system or device used in industrial processes to purify liquids or gases and recover valuable materials or components from waste streams. Here’s an overview of its features, functions, and applications:

Features:

1. Filtration Systems: Utilizes various filtration techniques such as mechanical filtration, microfiltration, ultrafiltration, or reverse osmosis to remove contaminants, particles, or impurities from liquids or gases.

2. Separation Technologies: Incorporates separation methods such as distillation, evaporation, crystallization, or membrane processes to separate desired components from mixtures or solutions.

3. Adsorption and Absorption: Uses adsorbents or absorbents to capture specific molecules or contaminants from fluids through surface interactions or absorption mechanisms.

4. Chemical Treatment: Includes chemical processes like oxidation, reduction, precipitation, or ion exchange to chemically alter or remove substances from the fluid stream.

5. Monitoring and Control: Often equipped with sensors, monitors, and automated control systems to ensure process efficiency, maintain quality standards, and optimize resource utilization.

6. Modular Design: Some units are designed in modular configurations to allow scalability, flexibility in operation, and easier integration into existing industrial processes.

Functions:

- Purification: Removes impurities, contaminants, pollutants, or unwanted substances from liquids (water, chemicals) or gases (air, exhaust gases).

- Recovery: Recovers valuable materials, components, or resources from waste streams or by-products of industrial processes, reducing waste and enhancing resource efficiency.

- Treatment: Treats wastewater, industrial effluents, or process streams to meet environmental regulations, recycling standards, or reuse criteria.

- Product Refinement: Refines and purifies products for specific industrial applications, improving product quality and consistency.

Applications:

- Water Treatment: Purification and recovery units are used in water treatment plants for potable water production, wastewater treatment, and water reuse/recycling.

- Chemical and Petrochemical Industries: Applied in refining processes, chemical synthesis, solvent recovery, and treatment of hazardous wastes.

- Mining and Metallurgy: Utilized for metal recovery from ores, effluent treatment, and tailings management.

- Food and Beverage: Used in food processing for ingredient purification, wastewater treatment, and resource recovery.

- Environmental Remediation: Deployed in environmental cleanup projects to treat contaminated soil, groundwater, or air emissions.

Benefits:

- Resource Conservation: Maximizes the recovery of valuable materials and minimizes waste generation, contributing to sustainable practices.

- Compliance: Helps industries comply with environmental regulations, discharge limits, and sustainability goals.

- Cost Savings: Reduces operational costs associated with waste disposal, raw material procurement, and energy consumption.

- Risk Mitigation: Minimizes environmental impacts, improves workplace safety, and enhances operational reliability.

In summary, purification and recovery units are essential systems in various industries for treating liquids and gases, recovering valuable resources, and ensuring compliance with environmental standards. They play a crucial role in enhancing efficiency, reducing environmental footprint, and promoting sustainable industrial practices.