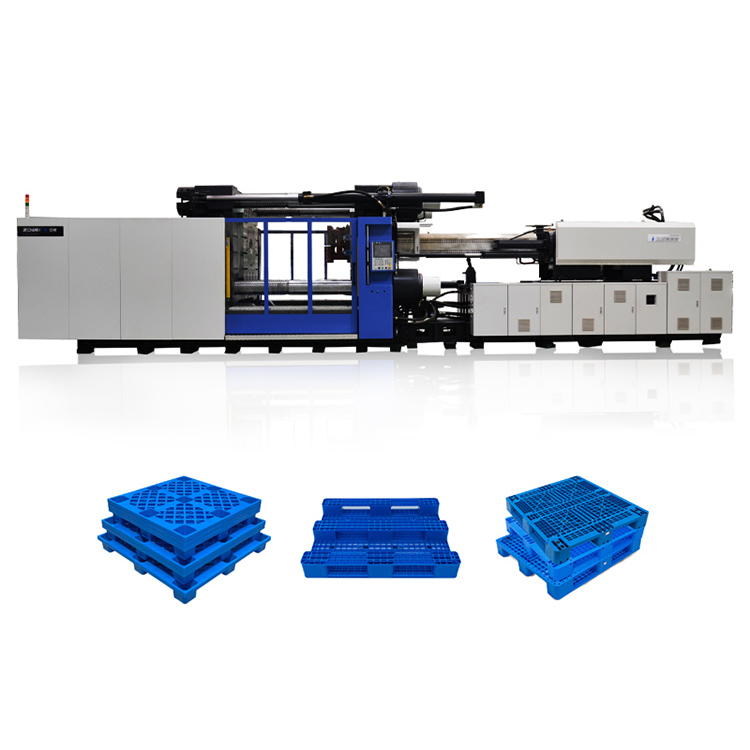

Features of a Plastic Pallet Injection Molding Machine

2024-02-23

A Plastic Pallet Injection Molding Machine is designed specifically for the production of plastic pallets using the injection molding process. Plastic pallets are widely used in logistics, manufacturing, and distribution industries for transporting goods. The injection molding machine for plastic pallets is specialized to handle the size, weight, and structural requirements of these large and durable products. Here are some key features and aspects of a Plastic Pallet Injection Molding Machine:

1. Clamping Unit:

- The machine is equipped with a powerful clamping unit capable of securely holding large molds designed for plastic pallet production.

2. Injection Unit:

- The injection unit is responsible for melting and injecting a large volume of plastic material into the mold cavity to form the plastic pallet.

3. Large Mold Capacity:

- Plastic pallets come in various sizes and designs, and the injection molding machine must have the capacity to handle molds that produce pallets of different dimensions and specifications.

4. Hydraulic System:

- Hydraulic systems are commonly employed in large-scale injection molding machines due to their power and ability to handle heavy loads. The hydraulic system controls the clamping and injection processes.

5. Cooling System:

- A reliable cooling system is crucial to ensure proper solidification of the molten plastic within the mold, maintaining the structural integrity and dimensional accuracy of the plastic pallet.

6. Automation:

- Modern machines often include automation features to enhance efficiency, such as automated mold changing systems, robotic systems for part handling, and other automated processes.

7. Control System:

- The machine is equipped with a control system that allows operators to set parameters such as injection speed, pressure, and temperature. Precise control is crucial for producing high-quality and consistent plastic pallets.

8. Material Handling System:

- A material handling system ensures a consistent and efficient supply of plastic pellets or resin to the injection molding machine for the manufacturing process.

9. Ejection System:

- After the plastic has solidified in the mold, an ejection system is used to release the molded plastic pallet from the mold.

10. Safety Features:

- Safety features, including emergency stops, interlocks, and safety guards, are incorporated to ensure the safety of operators and prevent accidents.

Plastic Pallet Injection Molding Machines play a crucial role in the manufacturing of plastic pallets, which are essential for material handling and logistics in various industries. The selection of a suitable machine depends on factors such as the size and weight specifications of the pallets, production volume, and customization requirements. Manufacturers can choose machines that best meet their specific production needs.