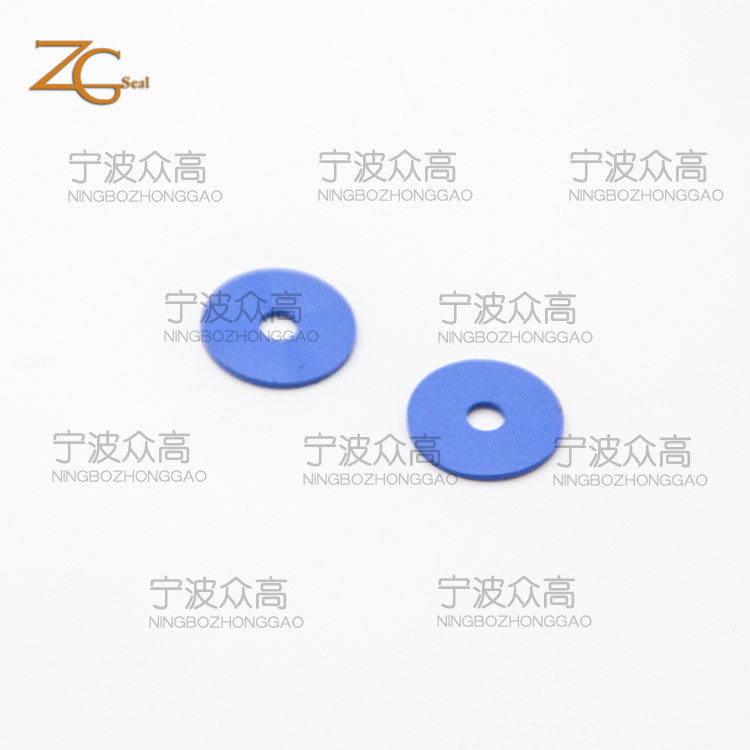

Detailed Overview of Rubber Gasket O Ring

2024-04-03

A rubber gasket O-ring, often simply referred to as an O-ring, is a type of mechanical seal commonly used in fluid systems to prevent the leakage of gases or liquids between mating surfaces. Here's an overview of its features and functionality:

1. Material: O-rings are typically made from various elastomeric materials, such as rubber (e.g., nitrile rubber, silicone rubber, EPDM rubber) or thermoplastic elastomers (e.g., fluorocarbon elastomers). The material selection depends on factors such as the operating temperature range, chemical compatibility, and application requirements.

2. Circular Cross-Section: O-rings have a circular cross-section, resembling a torus or doughnut shape. This design allows them to form a seal by filling the gap between two mating surfaces when compressed within a groove or recess.

3. Elasticity and Deformability: O-rings are highly elastic and deformable, allowing them to conform to irregularities or imperfections in mating surfaces. When compressed, the O-ring creates a tight seal, preventing the passage of fluids or gases.

4. Sealing Principle: O-rings function based on the principle of hydraulic pressure or mechanical compression. When subjected to pressure or compression between two surfaces, the O-ring deforms to fill any gaps or voids, creating a barrier that prevents fluid or gas leakage.

5. Versatility: O-rings are widely used in various industries and applications, including automotive, aerospace, plumbing, hydraulic systems, pneumatic systems, and machinery. They are suitable for sealing applications involving a wide range of temperatures, pressures, and fluid types.

6. Ease of Installation: Installing an O-ring is relatively straightforward. The O-ring is placed in a groove or recess machined into one of the mating surfaces. When the mating surfaces are brought together, the O-ring is compressed, forming a seal.

7. Chemical Compatibility: The material composition of the O-ring determines its resistance to different chemicals and fluids. It's essential to select an O-ring material that is compatible with the specific fluid or gas being sealed to ensure long-term reliability and performance.

8. Maintenance: O-rings require periodic inspection and replacement to maintain sealing integrity. Factors such as wear, aging, and exposure to harsh operating conditions can affect the performance of O-rings over time.

Overall, rubber gasket O-rings are essential sealing components that provide reliable fluid and gas sealing in a wide range of applications. Their simplicity, effectiveness, and versatility make them indispensable in numerous industries and systems where leakage prevention is critical.