Considerations related to belling equipment

2023-12-14

Belling is the process of forming a socket (bell) at the end of a plastic pipe to facilitate the connection with another pipe or fitting. The belling process is crucial for creating secure and leak-proof joints in pipelines.

Here are key components and considerations related to belling equipment:

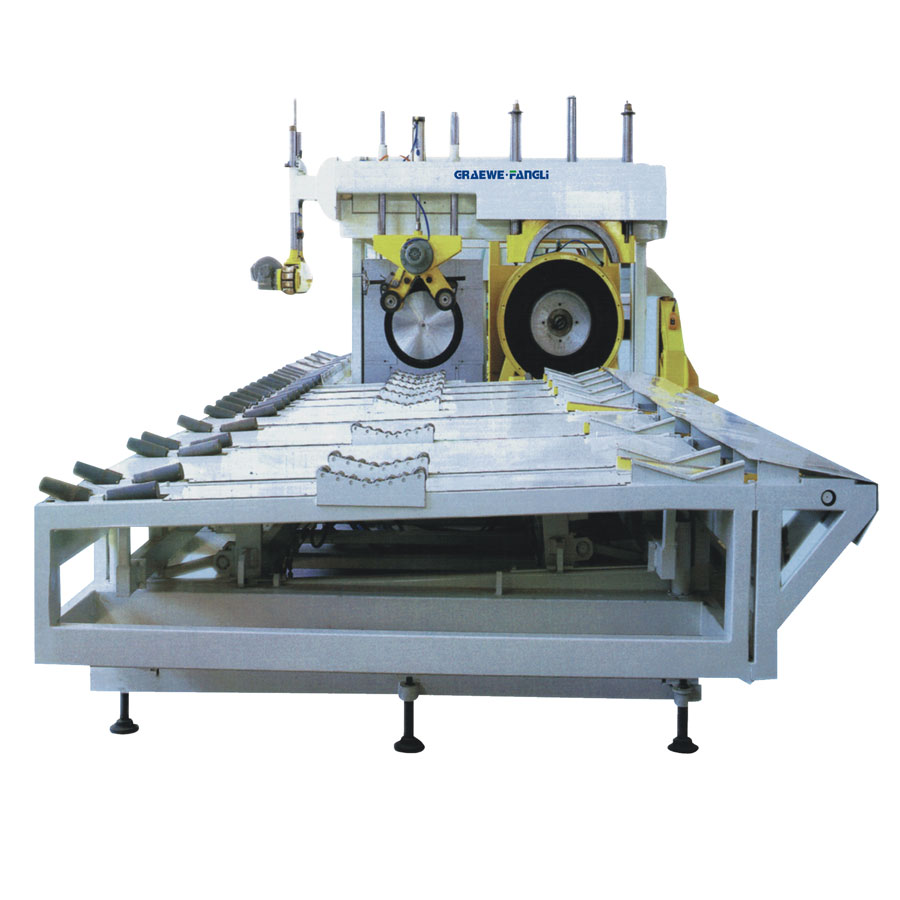

1. Belling Machines:

- Belling machines are the primary equipment used for forming the socket at the end of plastic pipes. These machines can use different methods such as solvent cement sockets, rubber ring sockets, or heat sockets, depending on the type of joint required.

2. Socket Types:

- Belling equipment can create various socket types, including solvent cement sockets (used in PVC pipes), rubber ring sockets (common in certain types of plastic pipes), and heat sockets (formed by heating and shaping the pipe end).

3. Automation:

- Some belling machines are automated, allowing for efficient and consistent production. Automation can be especially beneficial for high-volume manufacturing.

4. Adjustability:

- Belling equipment should be adjustable to accommodate different pipe sizes and types. This adaptability is crucial for versatility in production.

5. Heating Elements:

- In the case of heat sockets, belling equipment includes heating elements that soften the plastic pipe end for shaping. Precise temperature control is essential to achieve quality results.

6. Cooling Mechanism:

- After forming the socket, a cooling mechanism is often employed to ensure the socket retains its shape and strength.

7. Control Systems:

- Belling machines may have control systems that allow operators to set parameters such as heating temperature, cooling time, and other factors relevant to the belling process.

8. Integration with Production Lines:

- Belling equipment is often integrated into plastic pipe production lines, allowing for seamless and efficient manufacturing processes.

9. Quality Control:

- Quality control features are essential to ensure that belling is done accurately, meeting industry standards and specifications.

10. Safety Features:

- Belling equipment should include safety features to protect operators during the manufacturing process.

11. Maintenance and Serviceability:

- Easy maintenance and serviceability are important considerations to minimize downtime and ensure the longevity of the belling equipment.

Belling equipment plays a crucial role in the production of plastic pipes, contributing to the creation of reliable and durable joints in plumbing, construction, and various other applications.