Aspects of aircraft cables

2023-11-15

Aircraft cable, often referred to as aviation cable or wire rope, is a type of cable designed for use in aviation and aerospace applications. It is constructed to meet stringent standards and requirements for strength, flexibility, and durability. Aircraft cables play a crucial role in various applications within aircraft, such as control systems, flight control surfaces, and other critical components. Here are key features and aspects of aircraft cables:

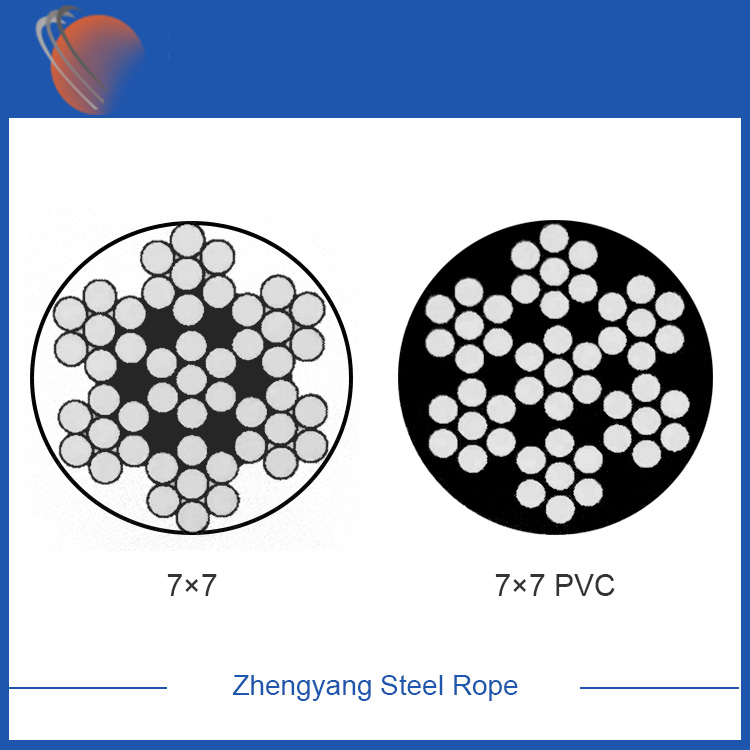

1. Construction:

- Aircraft cables are typically constructed using high-strength materials, often stainless steel or other alloys, to withstand the demanding conditions of aviation environments. The cables are composed of individual wires twisted together to form strands, and these strands are then twisted to create the final cable.

2. Strands:

- Similar to general wire ropes, aircraft cables consist of strands made up of individual wires. The number of wires in each strand and the arrangement of these strands can vary based on the cable's design and intended use.

3. Core:

- The core of an aircraft cable provides support to the strands and helps maintain the cable's structural integrity. The core can be made of various materials, including fiber cores or steel cores.

4. Lay:

- The lay of an aircraft cable refers to the direction of the twist in the wires and strands. The choice of lay depends on factors such as the application and the load direction.

5. Coatings:

- Aircraft cables may have coatings or treatments to enhance corrosion resistance and provide additional protection against environmental factors. Common coatings include galvanization or coatings with materials like zinc or nylon.

6. Diameter:

- Aircraft cables are available in different diameters, and the selection depends on the specific requirements of the application, including load capacity and space constraints.

7. Flexibility:

- Aircraft cables need to be flexible to allow for smooth movement and operation in aircraft control systems. The flexibility is achieved through the design of the cable and the choice of materials.

8. Tensile Strength:

- High tensile strength is a critical characteristic of aircraft cables, as they are often used in applications where the cable must withstand significant loads and forces.

9. Regulatory Compliance:

- Aircraft cables must comply with stringent regulatory standards and specifications set by aviation authorities, such as the Federal Aviation Administration (FAA) in the United States and other international aviation organizations.

10. Applications:

- Aircraft cables are used in a variety of applications within aircraft, including control cables for ailerons, elevators, rudders, and other flight control surfaces. They are also used in landing gear systems, engine controls, and other critical systems.

11. Inspection and Maintenance:

- Regular inspection and maintenance of aircraft cables are essential to ensure their continued reliability and safety. Any signs of wear, corrosion, or damage should be addressed promptly.

Aircraft cables are crucial components in ensuring the safe and reliable operation of aircraft. The materials and construction of these cables are designed to meet the demanding conditions of aviation, and they undergo rigorous testing and inspection to comply with aviation standards and regulations.