Aspects associated with color-marking co-extrude equipment

2024-02-29

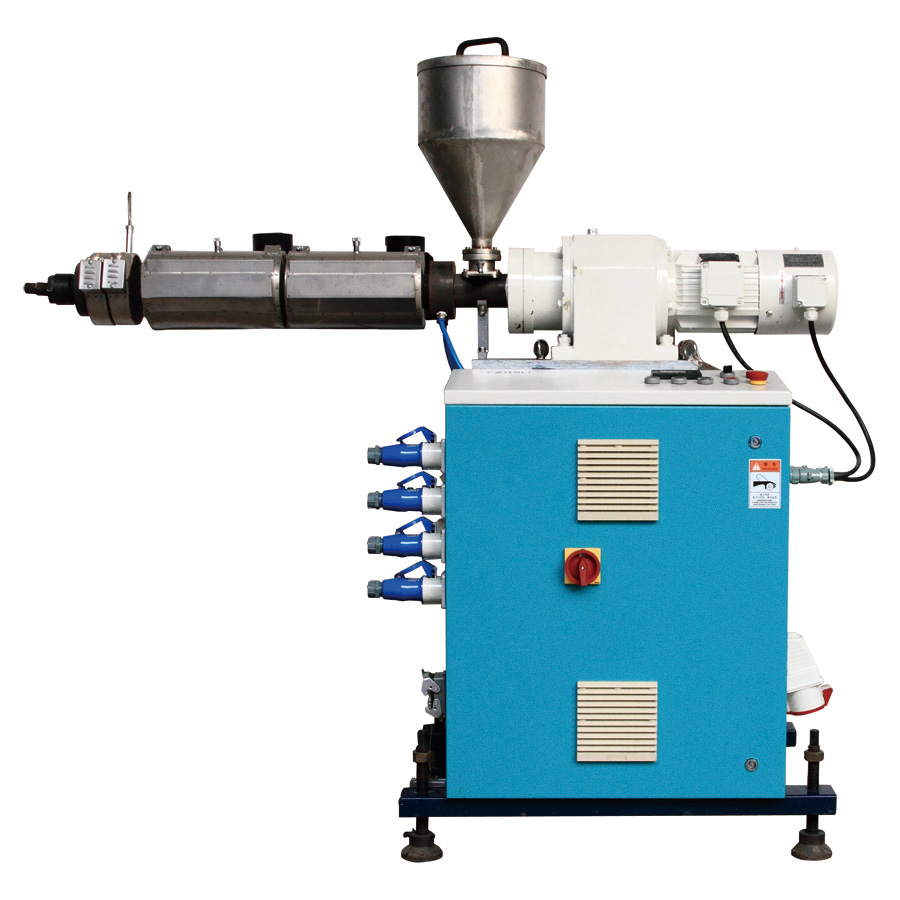

Color-marking co-extrusion equipment is a specialized machinery used in the plastics industry for producing extruded profiles or products with distinct color markings. Co-extrusion involves combining multiple materials or colors in a single extrusion process, and color-marking co-extrusion equipment is designed to achieve this with precision. Here are key aspects associated with color-marking co-extrude equipment:

1. Co-Extrusion Process:

- Co-extrusion involves extruding multiple materials simultaneously to create a single product with distinct layers or color patterns. Color-marking co-extrusion specifically focuses on incorporating colored markings into the extruded profile.

2. Material Compatibility:

- The equipment is designed to work with various plastic materials, including different colors and types. Compatibility is crucial to achieve the desired visual effect in the final product.

3. Color Control System:

- Color-marking co-extrusion equipment often includes a precise color control system. This system ensures accurate color blending and distribution throughout the extruded profile.

4. Multiple Extruders:

- Color-marking co-extruders typically have multiple extruders, each dedicated to a specific color or material. These extruders work in tandem to create the desired color pattern.

5. Die Design:

- The die, or shaping tool, is a critical component in achieving the desired color markings. The die design is customized to create the specific shape and color arrangement in the extruded profile.

6. Cooling and Sizing:

- After the extrusion process, the product needs to be cooled and sized accurately. Cooling systems and sizing equipment are integrated into the co-extrusion line to ensure proper product dimensions.

7. Inline Marking or Printing:

- Some color-marking co-extrusion equipment may include inline marking or printing systems. This allows for additional customization, such as adding text or logos to the extruded profile.

8. Material Handling:

- The equipment handles multiple materials simultaneously, ensuring a consistent flow and distribution of colors during the extrusion process.

9. Temperature Control:

- Temperature control is essential to maintain the proper viscosity of the plastic materials, especially when dealing with different colors or types of plastics.

10. Color Changeover Capability:

- Some advanced co-extrusion equipment is designed for quick color changeovers. This feature is beneficial for manufacturers producing different color patterns or changing production runs.

11. Quality Control Systems:

- Quality control mechanisms may be incorporated to monitor the color consistency, profile dimensions, and overall quality of the extruded product.

12. Customization Options:

- Color-marking co-extrusion equipment may offer customization options for creating various color patterns, gradients, or intricate designs in the extruded profiles.

13. Speed and Throughput:

- The equipment's speed and throughput capacity are crucial factors for efficient production. High-speed co-extrusion lines contribute to increased productivity.

14. Automation:

- Automation features, such as PLC (Programmable Logic Controller) systems, may be integrated for precise control and ease of operation.

15. Maintenance and Cleaning:

- Easy maintenance and cleaning features are essential for the smooth operation and longevity of the co-extrusion equipment.

Color-marking co-extrusion equipment is used in industries where visual aesthetics and color differentiation are critical, such as in the production of decorative trims, profiles, or products with specific color patterns. The equipment's design and capabilities vary based on the specific requirements of the extruded profiles and the desired color effects.