Applications of Iron Shaft Axle Bushings

2024-06-13

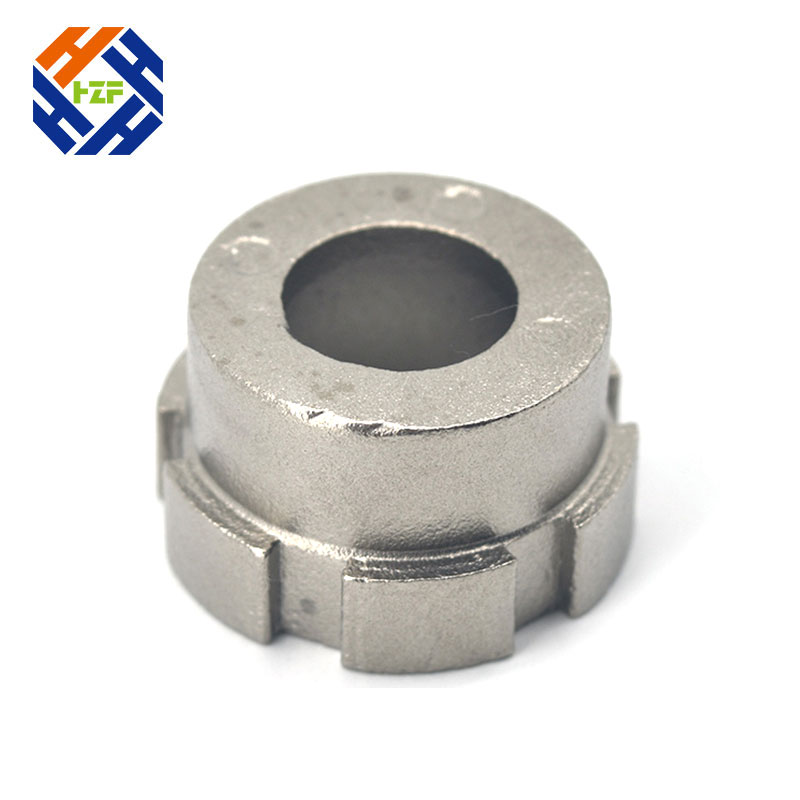

Iron shaft axle bushings, often referred to simply as bushings or bearings, are critical components in various mechanical systems. They are used to reduce friction between rotating shafts and stationary supports, thus enabling smooth and efficient motion. Here’s a brief overview of their purpose, types, materials, and applications:

Purpose

1. Reduce Friction: Bushings provide a surface for shafts to rotate or slide within, reducing friction and wear between moving parts.

2. Support Loads: They help in bearing radial and axial loads, maintaining the alignment of the rotating shaft.

3. Vibration and Noise Reduction: Bushings can also dampen vibrations and reduce noise in machinery.

Types

1. Plain Bushings: Simple cylindrical shape, used in low-speed, low-load applications.

2. Flanged Bushings: Have a flange at one end to provide additional support and reduce axial movement.

3. Thrust Bushings: Designed to handle axial loads, often used in combination with other types of bushings.

4. Sleeve Bushings: Cylindrical bushings used in a wide variety of applications.

5. Split Bushings: Can be easily installed or replaced without disassembling the shaft.

Materials

1. Iron: Durable and strong, suitable for heavy-duty applications.

2. Bronze: Offers good wear resistance and low friction.

3. Brass: Less durable than bronze, but cheaper and good for low-load applications.

4. Plastic/Polymer: Used in lightweight, low-load, and corrosion-resistant applications.

5. Composite: A combination of materials to provide specific properties such as enhanced strength and reduced friction.

Applications

1. Automotive: Used in wheel hubs, suspension systems, and steering components.

2. Industrial Machinery: Found in conveyor systems, motors, and gearboxes.

3. Aerospace: Used in landing gear and control surfaces.

4. Agricultural Equipment: Implements like plows and harvesters use bushings to withstand rough conditions.

5. Marine: Used in propeller shafts and rudder assemblies to handle saltwater environments.

Selection Criteria

1. Load Capacity: Choose based on the radial and axial loads the bushing will support.

2. Speed: High-speed applications require low-friction materials.

3. Environment: Consider factors like temperature, moisture, and exposure to chemicals.

4. Maintenance: Some bushings are self-lubricating, reducing the need for regular maintenance.

5. Cost: Balance between performance requirements and budget constraints.

Maintenance and Replacement

Regular inspection and lubrication (if required) can prolong the life of bushings. Signs of wear include increased vibration, noise, and play in the shaft. Replacing worn bushings promptly can prevent damage to other components.

Conclusion

Iron shaft axle bushings are essential for ensuring smooth and efficient operation of mechanical systems. By understanding their types, materials, and applications, you can select the appropriate bushing for your specific needs and ensure the longevity and performance of your machinery.