Non-Rising Stem Gate Valve China: Discover Its Key Features, Uses, and Benefits for Reliable Flow Control

2025-12-30

In the world of industrial flow control, finding equipment that combines efficiency, reliability, and durability can often feel like searching for a needle in a haystack. Yet, amidst the myriad of options available, one standout solution is the non-rising stem gate valve, a design that has revolutionized how industries manage fluid and gas systems. In China, where precision engineering meets robust manufacturing, these valves have become indispensable for countless applications, from oil and gas to water treatment and beyond. But what exactly sets them apart, and why are they gaining such widespread acclaim? With DRIFCO at the forefront of innovation, we're diving deep into the essential features, versatile uses, and undeniable benefits that make these valves a go-to choice for ensuring seamless, reliable flow control. Whether you're a seasoned engineer or simply curious about the mechanics behind modern infrastructure, this blog will unveil the secrets that keep industries running smoothly, sparking your interest in the tools that power our world.

Explore the Unique Design of Non-Rising Stem Gate Valves in China

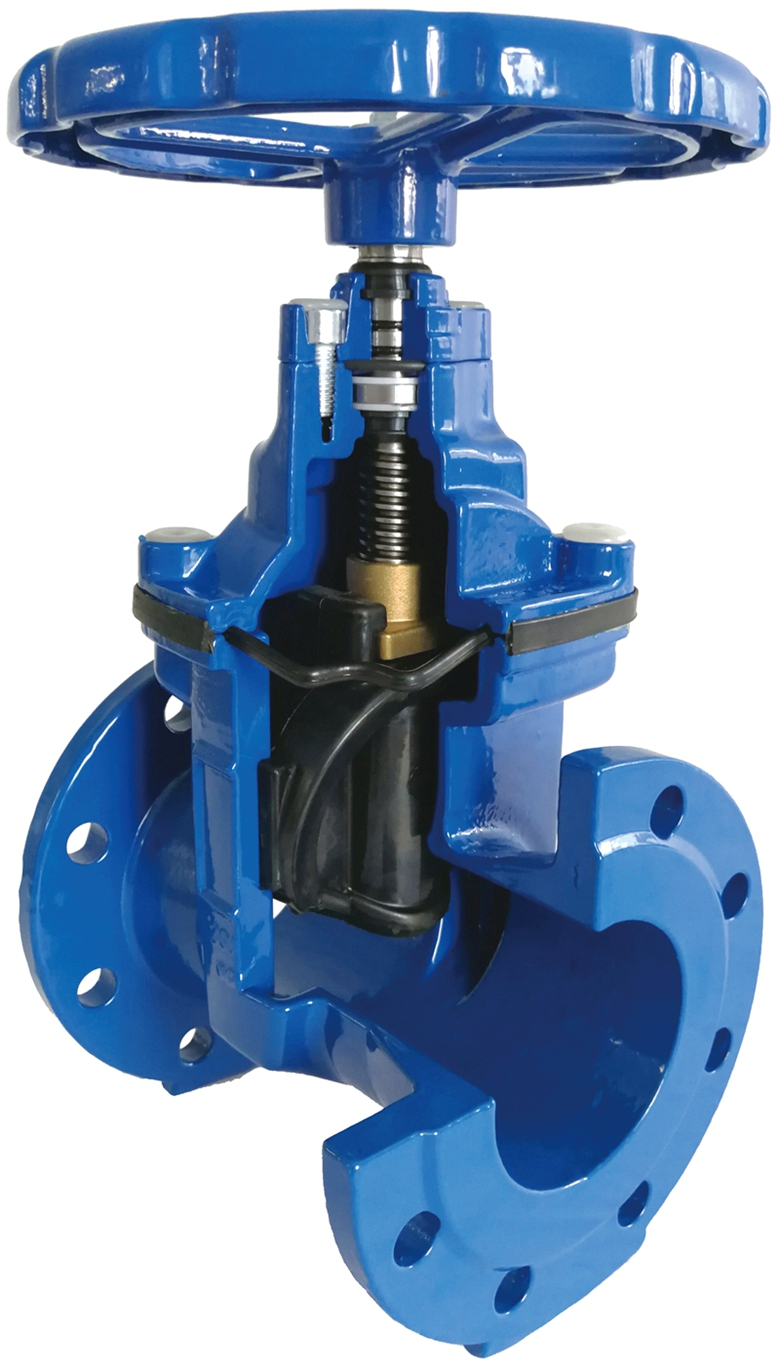

In the realm of industrial fluid control, Chinese manufacturers have carved out a distinct niche with their innovative non-rising stem gate valves. Unlike traditional designs where the stem visibly rises as the valve opens, these valves keep the stem stationary, a feature that proves invaluable in space-constrained environments like underground pipelines or tight machinery setups. This clever engineering not only saves precious vertical room but also reduces the risk of stem damage from external impacts, a common issue in harsh operational conditions. By focusing on this compact yet robust approach, China has tailored solutions that cater to global demands for efficiency and durability, often incorporating advanced materials like stainless steel or special alloys to withstand corrosive fluids, setting their products apart in competitive markets.

What truly sets these valves apart is their intricate internal mechanism, which often integrates a threaded stem that moves within the bonnet, driven by a handwheel or actuator. This design minimizes exposure to contaminants and wear, extending the valve's lifespan significantly. In China, manufacturers have pushed this further by customizing the sealing components—such as using flexible graphite or PTFE for tighter seals—to handle high-pressure applications without leaks. The result is a valve that operates smoothly with minimal maintenance, a key selling point for industries like oil and gas or water treatment where downtime is costly. This attention to detail reflects a broader trend in Chinese engineering: blending traditional robustness with modern precision to create tools that are both reliable and adaptable to diverse industrial needs.

Beyond functionality, the aesthetic and ergonomic aspects of these valves reveal a thoughtful design philosophy. Many Chinese models feature streamlined bodies and user-friendly interfaces, making them easier to install and operate even in remote locations. By emphasizing such practical enhancements, they've managed to stand out not just through technical specs but also through real-world usability, appealing to engineers who value both performance and convenience. This holistic approach—where every component, from the stem to the handwheel, is optimized for peak efficiency—showcases China's growing prowess in manufacturing specialized equipment that meets exacting global standards while offering unique competitive edges.

Uncover the Key Applications for Efficient Flow Management

Efficient flow management is more than just a buzzword—it's a game-changer for industries ranging from manufacturing to healthcare. At its core, it's about orchestrating processes seamlessly, whether that's optimizing supply chains to reduce bottlenecks or fine-tuning data pipelines for real-time insights. By focusing on key applications, organizations can pinpoint where flow improvements yield the highest returns, such as in logistics where route optimization cuts delivery times, or in IT where streamlined workflows boost team productivity. It's a practical approach that transforms chaotic systems into well-oiled machines, driving both cost savings and enhanced performance.

Dive deeper, and you'll find that effective flow management hinges on applications like predictive analytics and automation tools. For instance, in project management, using agile methodologies and Kanban boards helps visualize task progress, preventing overloads and ensuring deadlines are met. In customer service, dynamic routing systems direct inquiries to the right agents, slashing wait times and improving satisfaction. These applications don't just solve surface-level issues; they address underlying inefficiencies, fostering a culture of continuous improvement that keeps businesses agile in fast-paced environments.

Ultimately, mastering flow management means integrating tailored solutions across sectors. In finance, for example, automated transaction processing speeds up settlements while minimizing errors, while in retail, inventory management systems synchronize stock levels with demand spikes to avoid shortages. By uncovering and applying these key tools, companies can achieve a delicate balance between resource allocation and output quality, paving the way for sustainable growth. It's not about overhauling everything overnight, but strategically implementing the right applications to keep operations fluid and responsive to change.

Learn About the Advantages for Long-Term Reliability and Durability

When it comes to the benefits of long-term reliability and durability, it's essential to focus on how these attributes translate into real-world value for products and systems. Over time, robust designs and high-quality materials reduce the need for frequent repairs, which not only saves money but also minimizes disruptions in operations. This resilience ensures that investments continue to perform optimally, even under demanding conditions, providing peace of mind and a solid return on investment.

Durability goes beyond just lasting longer; it involves maintaining performance standards over extended periods, which enhances user trust and satisfaction. Products built with durability in mind often incorporate advanced engineering techniques that resist wear and tear, environmental factors, and technological obsolescence. This forward-thinking approach leads to fewer replacements and less waste, contributing positively to sustainability efforts while ensuring consistent functionality.

In practical terms, the advantages include reduced downtime and lower total cost of ownership, as durable components require less maintenance and have longer lifespans. By prioritizing reliability, manufacturers can deliver solutions that stand the test of time, fostering long-term relationships with customers and building a reputation for quality. This focus on enduring performance sets apart offerings in competitive markets, making them more appealing to those seeking dependable, long-lasting solutions.

Understand the Working Mechanism for Smooth Operation

To ensure seamless functionality, it's crucial to delve into how a system or device operates. By grasping the underlying principles, users can anticipate potential issues and intervene proactively, reducing unexpected downtime and enhancing overall reliability. This understanding isn't just about knowing what each button does; it involves recognizing the flow of processes, from input to output, and how various components interact. For instance, in mechanical systems, this might mean learning about friction, temperature effects, and material wear, allowing for timely maintenance and adjustments that prevent breakdowns. In digital tools, it could involve understanding algorithms, data handling, and connectivity protocols, enabling users to troubleshoot network glitches or software bugs efficiently.

Smooth operation often hinges on a deep, intuitive grasp of the working mechanism, which goes beyond surface-level instructions. When users comprehend the 'why' behind each function, they can adapt to changing conditions, such as fluctuating workloads or environmental factors, without relying solely on technical support. This insight fosters a sense of ownership and confidence, leading to more effective and sustained use. Consider how knowing the physics behind a bicycle's balance helps a rider navigate bumps or turns smoothly; similarly, in business software, understanding data structures can streamline reporting and decision-making. By embedding this knowledge through hands-on experience or clear guides, organizations can empower individuals, reduce errors, and maintain consistent performance.

Ultimately, mastering the working mechanism is key to fostering smooth, uninterrupted operation, as it transforms passive users into active participants who can prevent minor hiccups from escalating. This approach doesn't just fix problems reactively but builds resilience by anticipating needs based on how the system behaves under stress. In complex technologies like IoT devices or automated manufacturing lines, such comprehension ensures that maintenance schedules align with actual usage patterns, optimizing efficiency and longevity. By prioritizing this learning curve, we promote a culture of continuous improvement, where operations flow naturally and dependably, supported by a solid foundation of mechanistic insight.

Compare Benefits Over Traditional Valve Types in Various Industries

When comparing modern valve technologies to their traditional counterparts across different industries, it's clear that advancements in materials and design offer significant operational advantages. In sectors like oil and gas, for instance, newer valves often feature enhanced durability and precision, reducing downtime and maintenance costs compared to older models that may be prone to corrosion or leaks. This shift not only boosts efficiency but also supports compliance with stricter environmental regulations.

In the chemical manufacturing and water treatment industries, the benefits extend to improved flow control and safety. Modern valves, such as those with smart sensors or automated systems, can provide real-time monitoring and adjustments, minimizing human error and enhancing process reliability. This contrasts sharply with traditional manual valves, which might require frequent manual checks and adjustments, leading to higher labor costs and potential safety risks from mishandling.

Overall, adopting advanced valve types allows industries to achieve better performance, lower long-term expenses, and adapt to evolving technological demands, making it a strategic move for competitive advantage. These improvements span from enhanced energy savings in HVAC systems to reduced waste in food processing, showcasing the versatility and impact across diverse applications.

Discover Maintenance Tips to Ensure Optimal Performance

Staying on top of regular maintenance is key to keeping your equipment running smoothly and extending its lifespan. Simple checks, like monitoring fluid levels, tightening loose bolts, and cleaning filters, can prevent minor issues from turning into costly repairs down the line. By incorporating these tasks into a routine schedule, you'll not only boost efficiency but also save time and money in the long run.

Another effective approach is to keep a detailed log of all maintenance activities, noting any unusual sounds or performance dips you observe during use. This proactive tracking helps identify recurring patterns or potential weaknesses, allowing you to address them before they escalate. Tailoring your maintenance plan to your specific usage patterns—whether it's heavy daily use or intermittent operation—can further enhance reliability and ensure consistent output.

Finally, don't overlook the importance of staying informed about manufacturer updates and best practices for your particular model. Joining user forums or consulting with professionals can provide fresh insights and practical tips that might not be in the manual. Embracing a mindset of continuous learning and adaptation ensures your setup remains in peak condition, ready to handle whatever challenges come your way.

FAQ

A non-rising stem gate valve keeps the stem stationary and moves the gate vertically for operation, which is ideal for tight spaces unlike rising stem valves that lift the stem out.

They are commonly used in oil and gas pipelines, water treatment plants, and HVAC systems for precise flow control where space is limited.

Chinese makers often use materials like stainless steel or brass, along with strict quality control and compliance with ISO standards for long-term performance.

They require less maintenance due to fewer exposed parts and provide smooth, consistent operation with minimal leakage risk over time.

Yes, many models are designed to withstand extreme conditions, making them suitable for critical processes in chemical and power industries.

The fixed stem design allows for a smaller footprint, fitting into confined areas without needing extra clearance for stem movement.

Conclusion

Non-rising stem gate valves from China represent a sophisticated evolution in flow control technology, characterized by their compact design where the stem does not protrude during operation. This unique engineering allows installation in confined spaces while maintaining robust sealing capabilities through a rising gate mechanism. Chinese manufacturers have refined these valves with precision machining and materials like stainless steel or bronze to ensure durability under various pressures and temperatures. The design's hallmark is its ability to provide reliable shut-off with minimal maintenance, making it particularly valuable in industrial settings where space efficiency and long-term performance are critical.

These valves excel in applications ranging from water treatment and HVAC systems to chemical processing and oil refineries, offering smooth operation via a straightforward working mechanism that reduces friction and wear. Compared to traditional rising stem valves, they provide advantages such as lower installation height, enhanced safety in tight environments, and reduced risk of stem damage. To maintain optimal performance, regular inspections and lubrication of internal components are recommended. Overall, Chinese non-rising stem gate valves combine innovative design with practical benefits, delivering dependable flow control that supports efficiency and reliability across diverse industries.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com